Routine Maintenance of Internal Grinding Machines

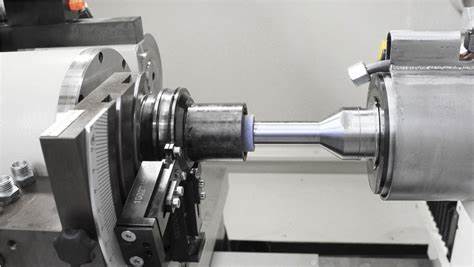

CNC Internal Grinding Machines are available for automotive parts, hydraulic parts, bearings, gears, sewing machine parts, motorcycle parts, aerospace and many other applications. How should we carry out routine maintenance on the internal grinding machine? This is an issue worthy of our careful consideration, do a good job, you can extend the service life of the grinder, so that it better serve us.

1. the machine running 600 hours for the first level of maintenance to the operator workers, repair workers to cooperate.

2. the first blocking the power supply, and then maintenance work.

一. External maintenance

1. Clean the surface of the machine tool, adhere to the internal clean, no rust, no yellow robe;

2. Make up, tighten the handle, hand ball, screws, nuts and other machine parts, adhere to the machine gauge;

3. Clean the grinding wheel frame, accessories and dust washer.

二.hydraulic

1. Check the hydraulic system, adhere to normal operation;

2. Cleaning oil pump, oil filter;

3. Cleaning linoleum, oil holes, adhere to the oil circuit is clear, oil quality, oil quality and quantity meet the requirements, the oil mark bright.

三.Cooling

1. Clean the cooling box, replace the coolant;

2. Cleaning cooling pump, filter.

四. electrical

1. Clean the motor, electrical box;

2. Clean the cooling pump and filter.