High Speed High Precision Vertical Three Axis Gear Shaping Machine

High Speed High Precision Vertical Three Axis Gear Shaping Machine

Stroke length:80-300mm

Max tooth width:70-280mm

Stroke speed :400-1500 str/min

Adopting vertical longitudinal layout and column feeding mode, it is applied to processing all kinds of disk/ shaft / oblique gear.

Main parts: bed, working table, center bed, column, tool holder, drive box, hydraulic station, chip conveyor, electric cabinet, etc.

This CNC vertical three axis gear shaping machine is designed for high speed and high precision gear cutting in industrial production environments. It is suitable for machining various gear types, including spur gears, helical gears, with stable accuracy and good repeatability. The machine is widely used for internal and external gear shaping in automotive transmissions, industrial gearboxes, and precision mechanical components where efficient production and consistent gear quality are required.

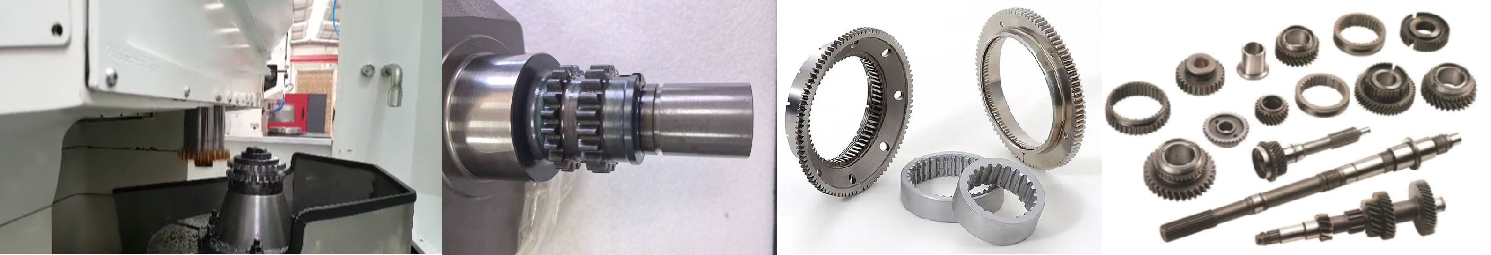

Typical Workpieces & Applications

Typical workpieces processed by this gear shaping machine include automotive transmission gears, industrial gearbox gears, internal gears, and external gear components. It is also suitable for machining precision shaft gears and complex gear parts that require accurate tooth profiles. The machine is ideal for manufacturers engaged in medium- to large-scale gear production where consistency, efficiency, and machining stability are critical.

Industry Applications

This CNC gear shaping machine is widely applied in automotive manufacturing, industrial transmission systems, and precision machinery industries. It is commonly used by gear manufacturers and component suppliers producing parts for vehicles, industrial equipment, and automated mechanical systems. The machine supports efficient production workflows while maintaining reliable gear quality across long-term operation.

machine functions

1.The machine is equipped with Siemens 828D numerical control system, three-axis numerical control.

X-axis: Realize radial feed and fast backward movement of the machine;

C2 axis: the rotation of the tool axis and the up and down reciprocating motion of the tool spindle

C1 axis: rotation of the table

S-axis: Stroke speed of the main movement

The feed rate, number of cycles and depth of cut can be set arbitrarily during machining, and automatic speed change is realized when roughing and finishing machining changeover.

2.High machining precision of the machine: high-precision worm gear indexing, worm gear grade ≤ national standard grade 2. Using AA grade gear shaping cutter, the precision of test piece meets GB/T 10095-2008 gear precision grade 6;

3.High machining efficiency of the machine tool: hydrostatic technology makes the maximum linear speed of the machine tool reach 90m/min and the average linear speed 60m/min, and the machine tool modal design is reasonable, so that the small tooth width parts can be processed under high stroke.

Items | GS200 | GS400 | GS600 | GS800 |

Max normal module (mm) | 4 | 8 | 10 | 16 |

Max machining diameter external tooth/inner tooth (mm) | 200 | 400/320+D cutter | 650/650+D cutter | 1000/1100 |

Stroke length (mm) | 80 | 130 | 230 | 300 |

Max tooth width (mm) | 70 | 120 | 210 | 280 |

Stroke speed (str/min) | 1500 | 1500 | 600 | 400 |

Distance between tool spindlel workbench center (mm) | -110-255 | -40-400 | 0-750 | 0-750 |

Distance from the spindle end face of the machine tool to the worktable end face (mm) | 140-270 | 200-400 | 235-550 | 300-650 |

Tool spindle runout (mm) | /or 300 | 0/300 | 0/350 | |

Main motor power (Kw) | 0.001 | 0.002 | 0.002 | 0.002 |

Total power of machine (Kw) | 11 | 11 | 18.5 | 30 |

Total power of machine (Kw) | 20 | 22 | 25 | 35 |

Weight (t) | About7 | About 9 | About 13 | About 20 |

main configuration

No. | Name | Model Specification | Manufacturer or Brand |

1 | System | 828D | Siemens |

2 | Servo Motor | Siemens | |

2.1 | Table motor servo | Siemens | |

2.2 | Tool holder body servo motor | Siemens | |

2.3 | Column feed servo motor | Siemens | |

3 | Electric cabinet air conditioner | Tongfei | |

4 | Main motor | 5.5Kw | Ultra-synchronous |

5 | Bearing | NSK,IKO | |

6 | Hydraulic station | JAPAN-NACHI | |

7 | Ball screws | NSK | |

8 | Linear guides | INA | |

9 | Chip conveyor | National Brand |

1.Thermal balance high rigidity bed:

Except for the GS200 with high-precision rail configuration, all other models are equipped with steel embedded guide rail structures.

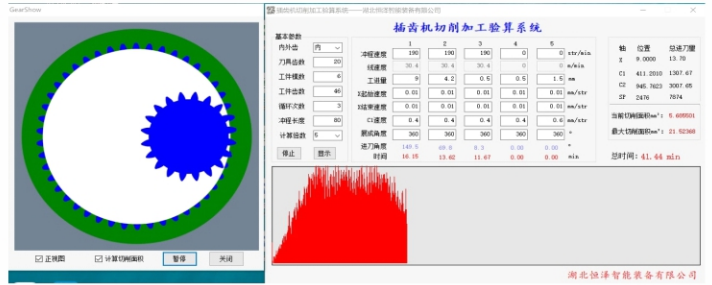

2.Gear Shaping Cutting Technology:

Gear shaping cutting generally includes single index cutting.traditional linear cutting, spiral cutting, variable feed cutting, and spiral decreasing cutting. The selection of each method and parameter requires multiple factors such as work piece, tool.machine tool,etc. Especially when choosing spiral decreasing cutting,professional software is required for calculation.

(1)Static geometrical accuracy of the machine:GB4686-84 is implemented.

(2)Working accuracy;Grade 6, execute GB/T10095.1-2001 GB/T10095.2-2001 standard.

(3)GB/T9061-1988 metal cutting general technical conditions.

(4)JB10167-2000 Gear Shaping Machine Safety Protection Technical Conditions.

(5)GB/T5226.1 General technical conditions for machine tool electrical equipment.

(1) A set of special tools and common tools.

(2) Technical data: instruction manual, electrical schematic diagram, ladder diagram, CNC system data, hydraulic schematic diagram, packing list and certificate of conformity.