Precautions When Using Universal Milling Heads

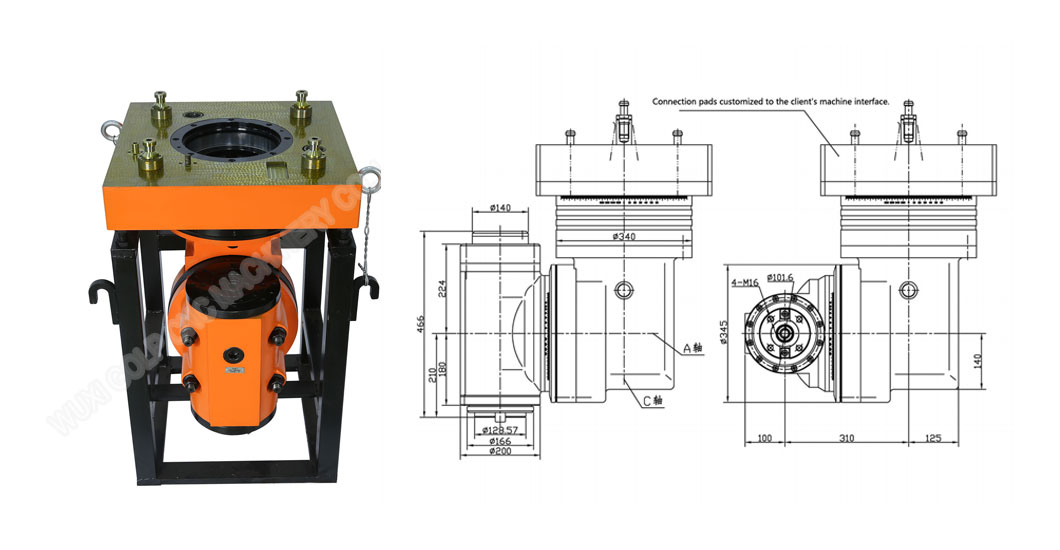

Universal milling head, also called universal angle head, is a kind of machine tool accessory. The centerline of rotation can be angled with the centerline of spindle rotation to process the workpiece. It is now widely used in various fields of machining, such as aviation, automobile, mold and so on. The use of milling head, without changing the structure of the machine tool can increase its processing range and adaptability, so that some of the traditional methods are difficult to complete the processing can be realized, and can reduce the repeated clamping of the workpiece to improve machining accuracy and efficiency.

Mainly used in machining centers and gantry milling machines, of which the light type can be installed in the tool magazine and can be freely converted between the tool magazine and the machine spindle; medium and heavy-duty with greater rigidity and torque, can be applied to most of the machining needs.

So what problems do we need to pay attention to when using it?

1. general milling head are used non-contact oil seal, in the process of machining, such as the use of cooling water, you need to run before spraying water, and adjust the direction of the cooling water nozzle, so that it is sprayed towards the cutting tool, you can avoid the cooling water penetrate into the body, in order to extend the life.

2. Avoid running at the highest speed for a long time.

3. Refer to the parameter characteristics of the milling head, and use it under appropriate machining conditions.

4. Before use, make sure the machine is warmed up after a few minutes of trial operation. Whenever machining, select the appropriate speed and feed for machining. Machining speed, feed and depth of cut should be adjusted in a gradual manner until the maximum machining efficiency is obtained.

5. general standard milling head machining, need to avoid processing will produce dust, particles of the material (such as: graphite, carbon, magnesium and other composite materials, etc.).