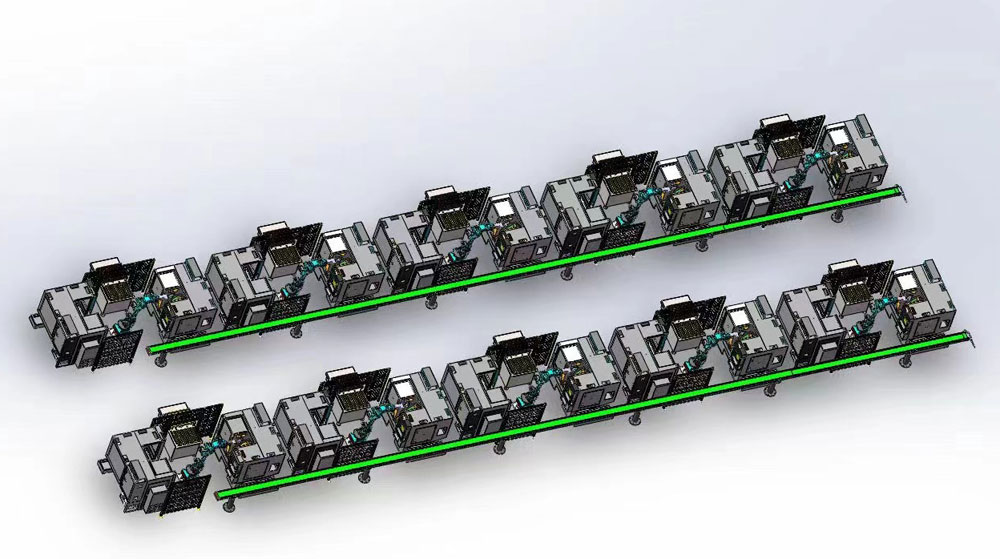

Automatic loading and unloading device for CNC lathe machining

In the modern manufacturing industry, CNC lathe has become a key production equipment, widely used in automotive, aviation, medical equipment and other industries, in order to further improve production efficiency and reduce the burden of operators, CNC lathe machining loading and unloading equipment came into being.

CNC lathe machining automatic loading and unloading is mainly composed of loading and unloading device, workpiece fixture, control system, etc., and its workflow is as follows: before the start of production, the operator needs to set the parameters of the system, the operator will be the raw material or workpiece placed in the loading device, and then start the system, the loading device will be the workpiece into the CNC lathe, the CNC lathe according to the pre-set parameters to start machining the workpiece, processing is complete, the lower material When the processing is completed, the loading device will take the workpiece off the CNC lathe, and the whole process will be in a continuous cycle to produce parts continuously.

The characteristics of CNC lathe machining loading and unloading

1, a high degree of automation: the equipment can run continuously with little or no human intervention, thus greatly improving productivity.

2、Precision: CNC technology and automation control ensures high precision and consistency of the workpiece.

3、Saving labor costs: reduces the need for skilled operators, thus reducing production costs.

4、Quick switching: It can be quickly adapted to different parts and production requirements, which improves flexibility.