Gear Chamfering Failure And Cause Analysis

Large thickness chamfering is more difficult, to a certain extent, by the corrosive conditions of electrical discharge machining, until the current occurs short-circuit and there is no discharge before the process is very unstable. As the tension burns, the wire will quickly break. In very unstable machining, the cutting surface will also form a bar-shaped groove, seriously affecting the surface quality. Gear chamfering crevices are filled with very viscous corrosion products, even almost powdery carbon black and corrosion particles.

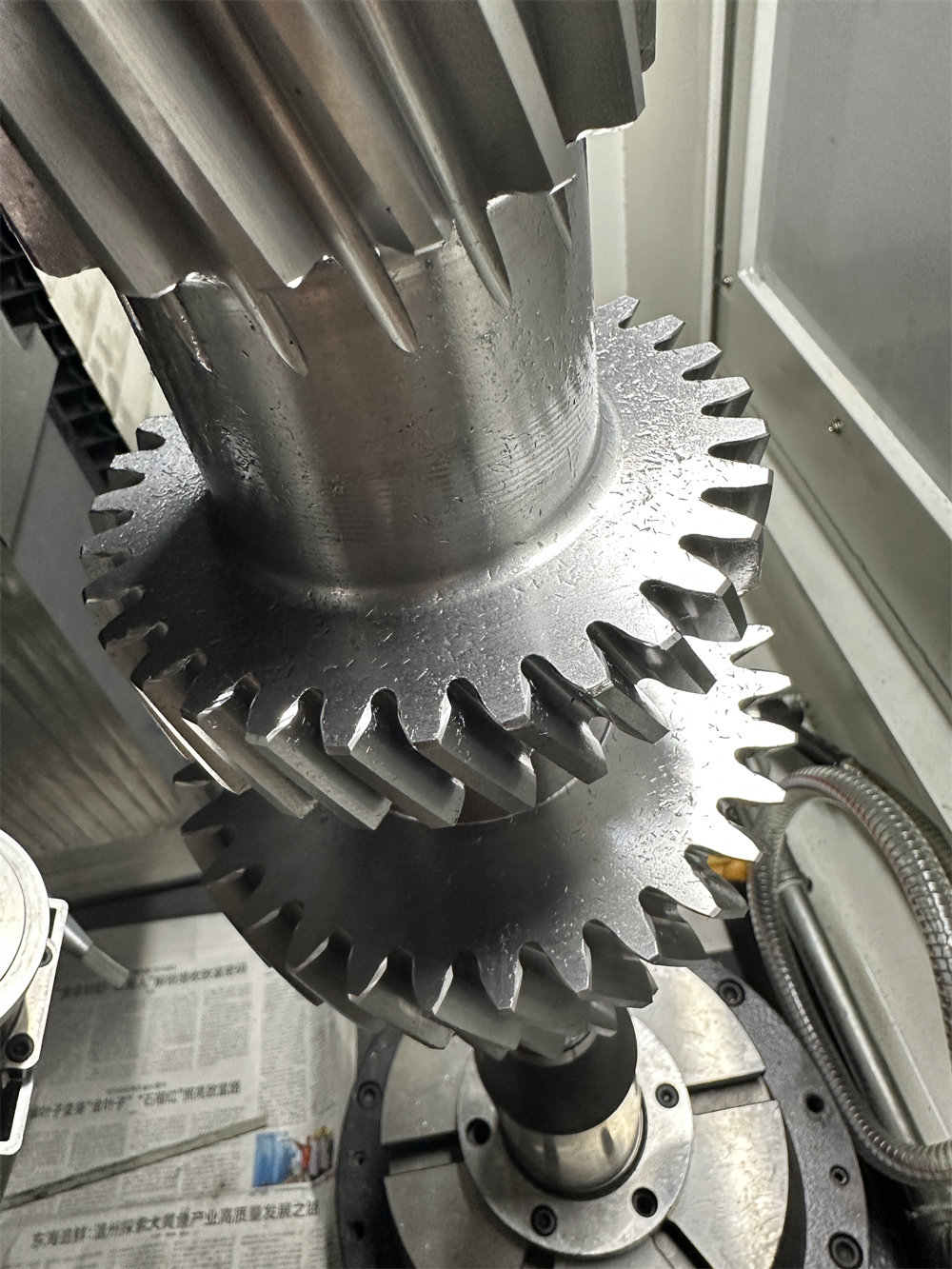

Gear chamfering angle is specialized for chamfering with large margin, the maximum chamfering depth is 15MM, the maximum chamfering surface width is 20MM, and the adjustable angle range is 30-60 degrees. It is suitable for welding steel plates, cast iron, hard plastics and non-ferrous metals. Pipe beveling, etc. The equipment is light weight, low vibration, stable operation, easy to use and safe.

The main reason for failure is that the lifting motor of the pneumatic gear chamfering angle is damaged. When the main gear chamfering angle is lifted, the lifting screws and the screw mother drive system are severely worn, and abnormal sound or no lifting. The inner threaded buckles fall off; foreign matter (e.g. stone chips) sticks to the chromatography column; the clearance between the lifting slider and the column is too small and the resistance is too high. The following measures are recommended: replace the angle lifting motor with a new one; firstly empty the motor and check whether the motor is qualified; check the lifting screws and nuts and repair or replace them; remove the dust and other foreign matter on the lifting column; reasonably adjust the clearance between the lifting slider and the column; replace the damaged bearing.