Application areas and working principle of crankshaft grinding machines

Crankshaft grinder is a precision CNC machine tool mainly used for precision grinding of crankshafts in engines, compressors and other mechanical equipments to ensure that the dimensional accuracy, shape accuracy and surface roughness of the crankshafts meet the strict design requirements.

Principle of operation

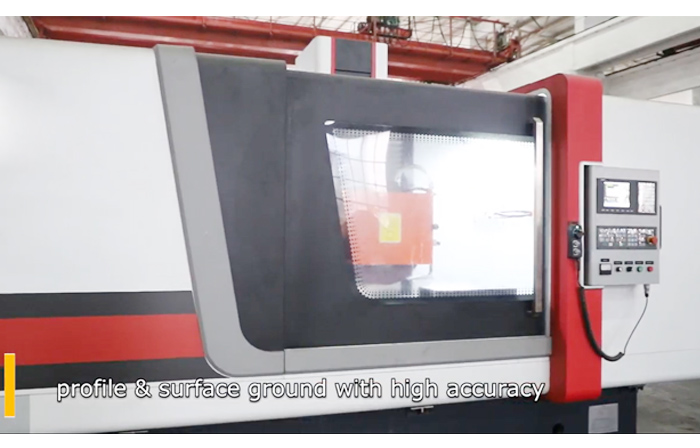

The operating principle of crankshaft grinding machines is based on precision grinding technology. The grinding machine is equipped with a special grinding wheel headstock, which can be used to grind the main journal, connecting rod journal and crank pin journal of the crankshaft according to the specific shape and dimensions of the crankshaft by controlling the feed amount, rotational speed and reciprocating travelling path of the grinding wheel through the CNC system. During the grinding process, the crankshaft is fixed on a chuck and the grinding wheel contacts the surface of the crankshaft, removing the metal layer by means of high-speed rotation and micro-feed to achieve the required dimensional accuracy and surface finish.

Application Fields

Automobile manufacturing industry: The crankshaft of an automobile engine is one of its core components, which needs to be precisely ground by the crankshaft grinding machine to ensure the smooth and durable operation of the engine.

Internal combustion engine manufacturing: the crankshafts of various internal combustion engines, such as diesel engines and petrol engines, need to be finished by crankshaft grinding machines.

General machinery manufacturing: many mechanical equipment, such as air compressors, generators, pumps, etc. The power transmission part may also involve the crankshaft, the same need for crankshaft grinding machine for the final precision machining.

Ship power equipment: ship engine crankshaft because of its large size, high precision requirements, but also inseparable from the support of crankshaft grinding machine.

In short, crankshaft grinding machines are widely used in any field that requires precision crankshaft parts, and they are one of the key production equipments to guarantee the reliability and life of mechanical equipment operation.