How does a dressing wheel work in a gear grinding machine?

The dressing wheel dresser plays a vital role in a gear grinding machine, its main job is to ensure that the grinding wheel maintains the ideal tooth profile in order to accurately grind the gear tooth flanks to meet the design requirements. The following is a brief explanation of how a dressing wheel works in a gear grinding machine:

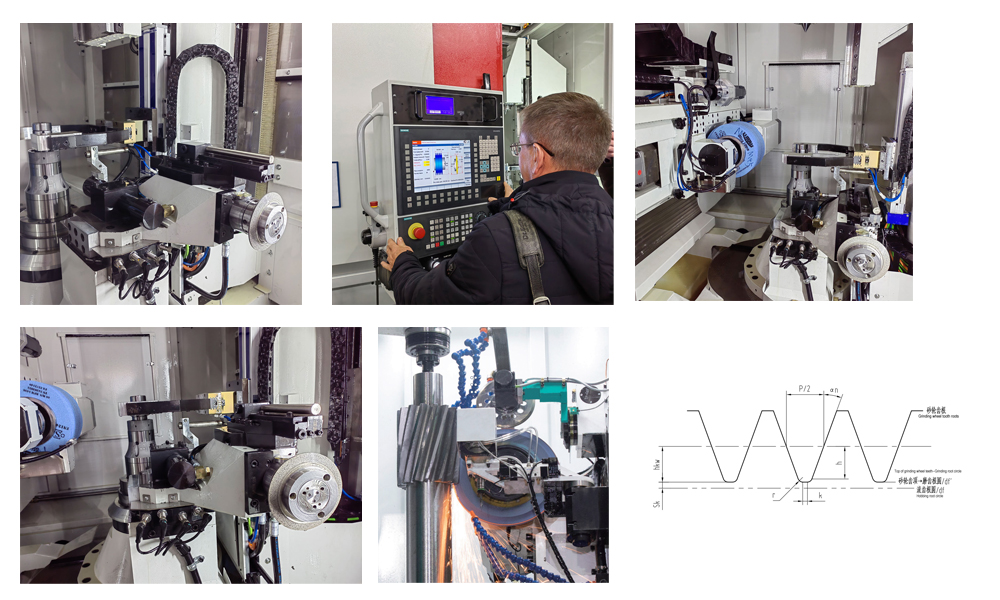

Dressing Wheel Material

Dressing wheel dressers are usually made of high-quality diamond material, which, with its extremely high hardness and good wear resistance, is able to accurately remove excess abrasive particles from the surface of the grinding wheel to form an accurate tooth profile. There are two main methods of grinding teeth in the sharpening process - the form method and the spreading method, either of which requires regular dressing of the grinding wheel.

Principle of operation

In a profile grinding machine, a dressing wheel is set to match the desired gear tooth profile, and by contacting and removing the excess of the grinding wheel, the wheel replicates the exact profile of the target gear tooth. In spreading grinding, the wheel simulates an imaginary rack of infinite length, and the dressing wheel follows a standard template of an involute or other tooth profile.

Improved Efficiency

In practice, the dressing wheel or diamond pen can precisely control the dressing path and depth according to the CNC program, and utilizes a high-precision servo drive system to ensure that the grinding wheel is accurately and uniformly dressed at high rotational speeds. Through real-time monitoring and compensation of grinding wheel wear, the whole grinding process can be carried out under strict quality control, and the final output of gear products with standardized precision and surface quality. At the same time, the introduction of modern CNC system greatly improves the automation level and working efficiency of the dresser, reduces human error, and realizes the batch production of precision grinding.