Types and Selection of Profile Grinding Wheels

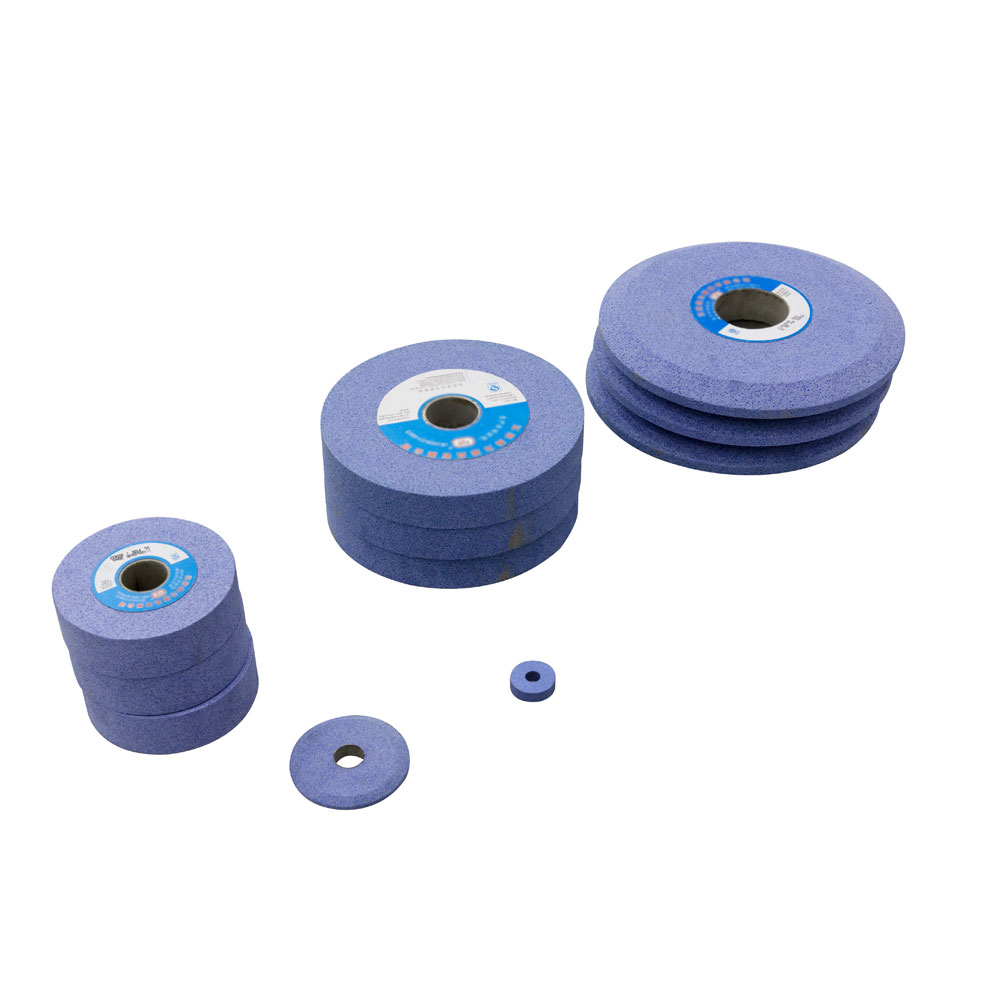

Profile Grinding Wheels are primarily used to machine the surface of a workpiece with a specific profile or shape on a grinding machine. These wheels can be customized to fit the shape of the desired finish to accommodate the grinding needs of different parts.

Types of Grinding Wheels:

- Straight-edged wheels are typically used for flat grinding;

- Tapered wheels are used for grinding angled surfaces;

- Disc and disk grinding wheels are mostly used for internal grinding or complex shapes.

The following factors need to be considered when selecting a profile grinding wheel:

1. workpiece materials: the hardness of different materials varies, such as silicon carbide is suitable for cast iron and non-ferrous metals, while aluminum oxide is widely used in the grinding of steel materials.

2. Processing accuracy: for high precision requirements of the processing task, you need to choose a higher precision grinding wheel, and the grinding wheel size tolerance needs to be strictly controlled.

3. Surface roughness requirements: according to the required surface roughness Ra value to determine the grain size of the grinding wheel, fine-grained wheels can obtain a better surface finish.

4. grinding wheel structure: including grinding wheel diameter, thickness and center hole size, etc. These parameters must be matched with the machine tool used.

5. Grinding method: Different grinding methods (e.g. face grinding, cylindrical grinding, etc.) have different requirements for grinding wheels.

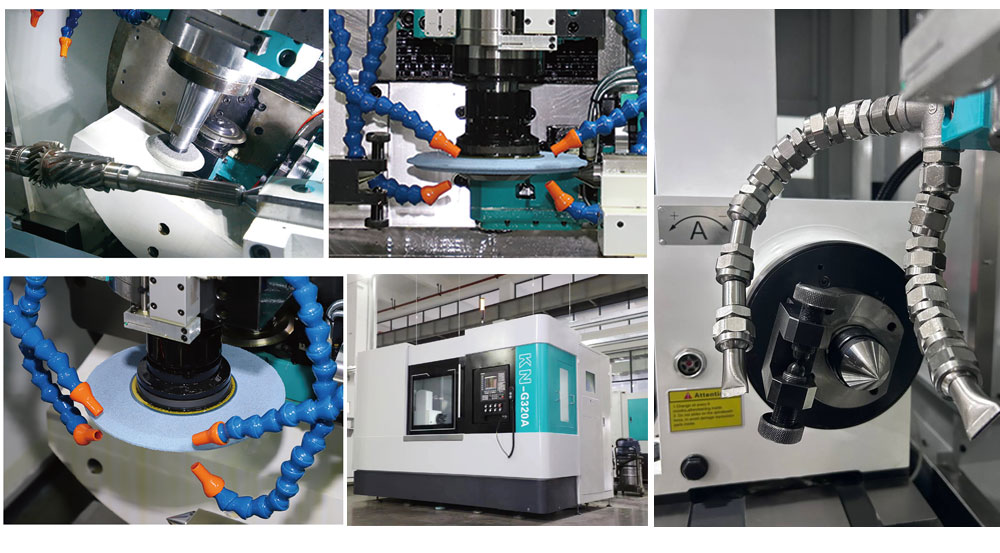

Profile grinding wheels are mainly used in profile grinding machines, tool grinding machines and other specialized machines to achieve efficient and precise shape grinding. Choosing the right grinding wheel not only improves processing efficiency, but also ensures the quality of the workpiece.