Part 1:Gearbox Types and Structures Explained Clearly

What Is a Gearbox?

A gearbox is a mechanical device used to alter the speed and torque of an output shaft. It achieves this transformation through a series of intermeshing gears that adjust the rotational speed and torque between the input and output shafts. Gearboxes are widely applied in various mechanical systems, such as automobiles, machine tools, and wind turbines, to meet specific speed and torque requirements in different applications.

Gearboxes can be classified according to various criteria, including transmission type, structural form, and application field.

Below are some common classifications and descriptions:

1. Classification by Transmission Type

Parallel Shaft Gearbox: The input and output shafts are arranged in parallel, suitable for applications requiring straight-line torque transfer.

Right-Angle (Vertical) Gearbox: The input and output shafts are positioned at a 90-degree angle, commonly used to change torque direction.

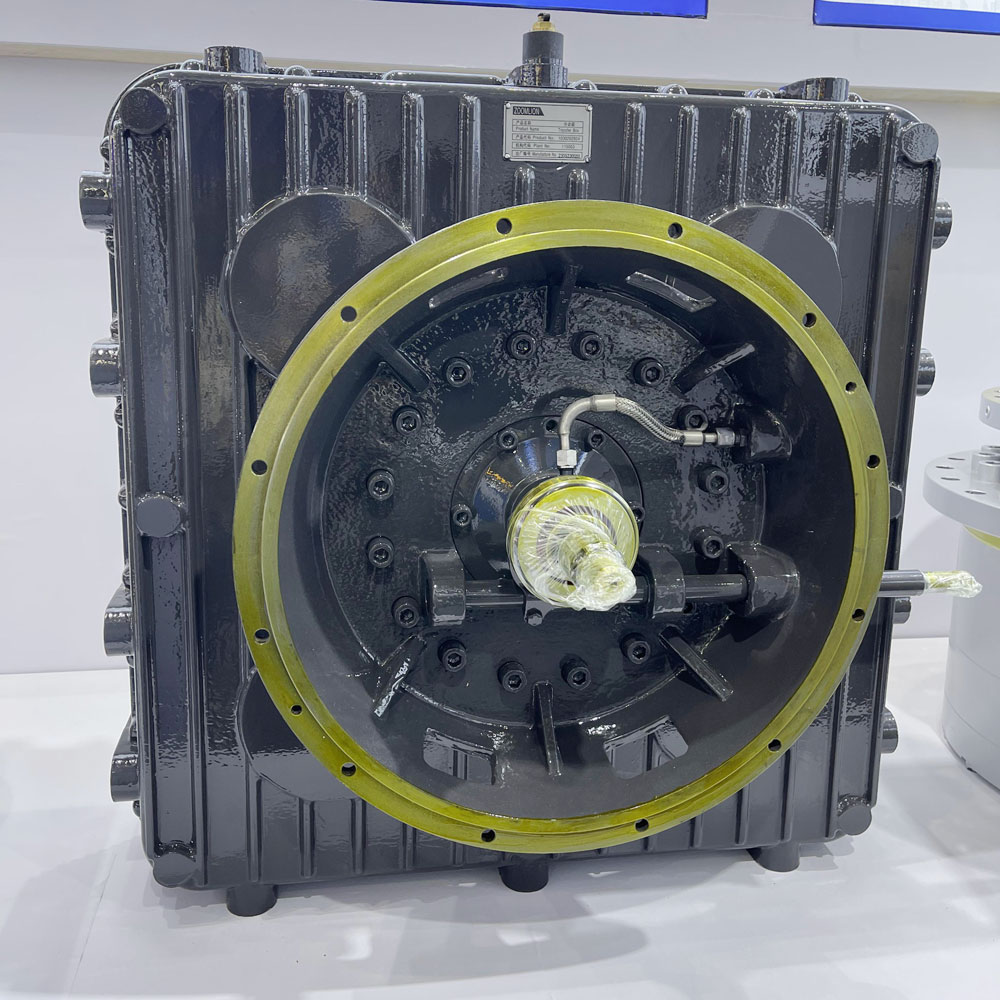

Planetary Gearbox: Composed of a central sun gear, multiple planet gears, and an outer ring gear, this design provides high efficiency and a compact structure, ideal for high-torque output applications.

Worm Gearbox: Uses a worm to drive a worm wheel; features self-locking ability and is suitable for low-speed, heavy-load scenarios.

2. Classification by Structural Form

Single-Stage Gearbox: Contains only one pair of gears, suitable for minor speed changes and space-constrained setups.

Multi-Stage Gearbox: Consists of multiple single stages, enabling larger speed ratios and torque adjustment, ideal for applications needing substantial speed or torque changes.

Mdular Gearbox: Allows users to customize the configuration by combining different modules, enhancing flexibility and adaptability.

3. Classification by Installation Method

Horizontal Mounting: Input/output shafts are horizontally oriented, common in ground-mounted equipment.

Vertical Mounting: Shafts are oriented vertically, used in lifting mechanisms and applications requiring vertical motion.

Foot Mount with Swing Base: Mounted on adjustable base feet, offering slight angle adjustments, often seen in belt conveyor systems.

Torque Arm Mounting: Stabilized using a torque arm on the side, preventing undesired rotation during operation.

4. Classification by Application Field

Industrial Gearboxes: Used in machinery on industrial production lines, such as conveyors and mixers.

Automotive Gearboxes: Includes manual transmissions, automatic transmissions, and dual-clutch systems, essential for vehicle powertrains.

Wind Power Gearboxes: Designed for wind turbines to convert low-speed, high-torque rotor motion into high-speed generator input.

Aerospace Gearboxes: Lightweight, high-precision, and reliable, used in aircraft control systems and more.

Each type of gearbox has its own design characteristics and application scenarios. Selecting the right gearbox is crucial for ensuring optimal mechanical system performance. Understanding these classifications helps match gearboxes to specific needs more effectively.

Four Common Gearbox Mounting Methods

1. Horizontal Mounting

Simple Explanation: The gearbox is installed "lying flat," with shafts placed horizontally.

Typical Applications: Commonly used in conveyors, mixers, and fans.

Visual Clues:

Horizontal input/output shafts

Flat base with mounting holes

Overall horizontal orientation

✅ Common Types: Parallel shaft helical gear reducers, coaxial gear reducers

2. Vertical Mounting

Simple Explanation: The gearbox is installed "standing up," with shafts oriented vertically.

Typical Applications: Used in hoists, lifting platforms, and some mixers.

Visual Clues:

Vertical input/output shafts

Support feet or flange mounting

Output shaft may point downward to connect to the load

Note: Ensure proper lubrication—some models require specially designed oil pathways.

3. Foot Mount with Swing Base

Simple Explanation: The gearbox is fixed using a base with adjustable angles.

Typical Applications: Useful in systems requiring installation flexibility, like belt conveyors.

Visual Clues:

Mounting holes at the base

Visible foot structures

Provides a stable and simple setup

✅ Advantage: Easy installation, suitable for most ground-mounted scenarios.

4. Torque Arm Mounting

Simple Explanation: A “torque arm” is used to fix the gearbox and prevent it from rotating.

Typical Applications: Common in systems with reverse torque, such as belt conveyors and winches.

Visual Clues:

A visible rod or arm attached to the gearbox side

One end connects to the gearbox, the other to the frame or equipment

✅ Feature: Saves space underneath; ideal for hanging or side-mount installations.

Common Gearbox Procurement Fields

Wind Energy: The wind turbine main gearbox is a critical component connecting the rotor (blades) to the generator, converting wind energy into electrical power.

Construction Machinery: Heavy equipment like excavators and loaders use gearboxes to transmit power and operate under high-load conditions.

Metallurgy, Chemical, and Paper Industries: Gearboxes provide reliable and efficient power transmission in various industrial machines.

Automotive Industry: Vehicle transmissions are a classic application, enabling the engine’s speed and torque to match different driving conditions.

Aerospace: High-performance gearboxes are essential for aircraft landing gear, flaps, and other mechanisms, requiring precision and reliability.

Shipbuilding: Gearboxes are used in propulsion and rudder systems to convert and transfer engine power.

Agricultural Machinery: Tractors and other farm equipment commonly use gearboxes in their powertrain systems.

Energy Sector: Besides wind power, gearboxes are also found in other renewable energy projects like hydropower and tidal energy.

Stay tuned for more insights on gearboxes, including gearbox precision grades, transmission stages, and more.

learn more: Part 2:Gearbox Basics-Essential Knowledge for Beginners

Understanding the Difference Between Gearbox and Reducer