High-Efficiency Dual-Station Induction Heating Machine

Comprehensive Overview of the Induction Heating Machine

The induction heating machine described here adopts a dual-station pass-through structure, consisting of an internal cavity quenching station and a spline quenching station. The internal cavity quenching station uses a three-jaw gripper (hollow chuck) to hold the workpiece handle (or the upper end outer circle of the workpiece). During quenching, the workpiece rotates while the inductor remains fixed. For spline and shaft quenching, the workpiece also rotates, with a lower tray (positioned by the inclined surface of the workpiece shell inner bore and the end face) and an upper center pressing down.

The main control of the induction heating machine uses a Siemens 828D CNC system to realize automatic control of the quenching process program. The equipment is equipped with a process data monitoring system for monitoring, recording, querying, and printing process parameters. The quenching liquid collection tank is separated from the bed, with a dedicated return pump to circulate the quenching medium back to the filtering system.

Machine Bed

The bed is a welded structure (C-section steel and square tube), stress-relieved by annealing before machining. The quenching transformer part is completely isolated from the quenching zone.

Feeding Conveyor

Composed of a loading station, barcode scanning station, and end-face positioning station, the conveyor uses a flat chain to move workpieces sequentially into the stainless steel feed chain, driven by an AC motor. Once at the end, a pusher cylinder pushes the workpiece into the secondary positioning fixture for precise end-face positioning.

Loading/Unloading Manipulator

Consisting of a rotation mechanism, lifting slide, and claw, the internal cavity loading manipulator uses a hollow three-jaw chuck to handle loading, clamping, rotating, and transferring. Servo motors drive the manipulator’s rotation and lifting via precision roller screws, with adjustable speed and position settings on the CNC. Protective telescopic covers reduce smoke and dust pollution.

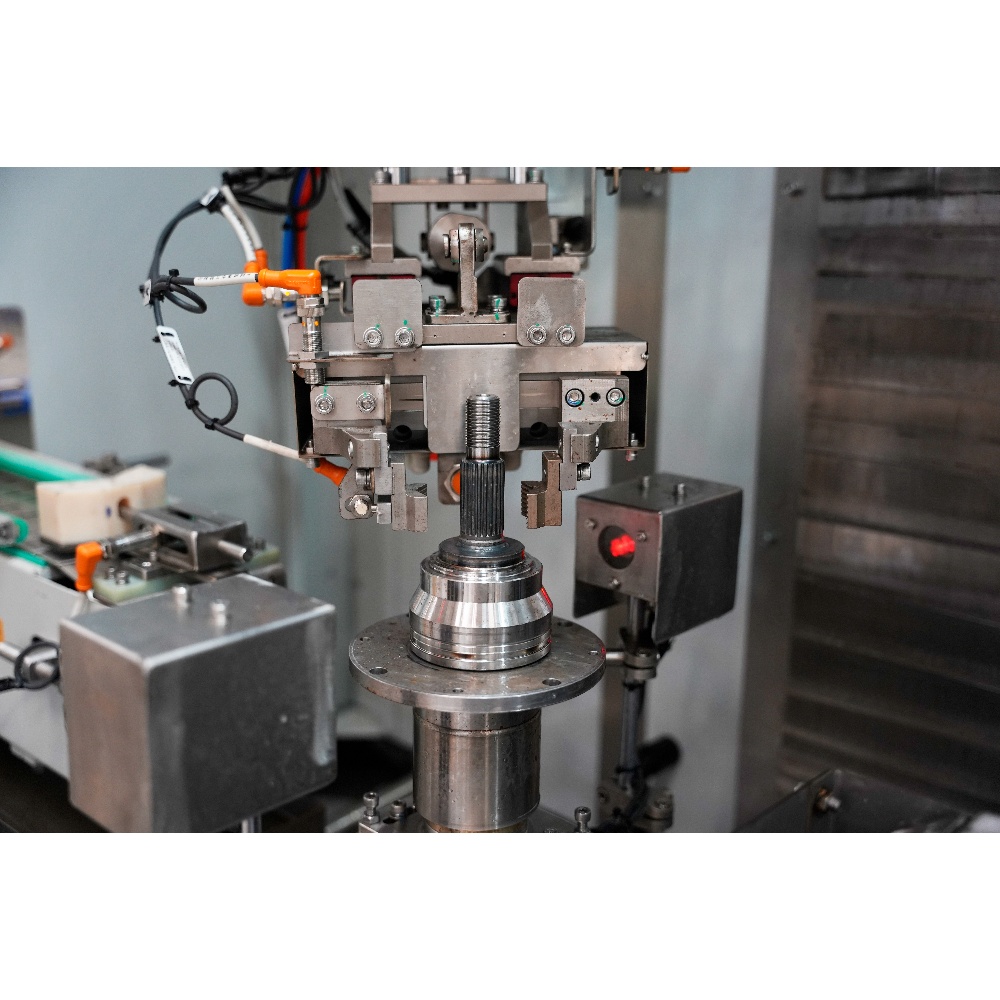

Internal Cavity Quenching Station

Here, the manipulator grips the spline (with the ball groove facing down), rotating it via an AC motor. Stainless steel grippers provide excellent corrosion resistance. Rotational speed is digitally adjustable and monitored. Clamping blocks in contact with the workpiece are removable and replaceable.

Transformer Slide

The transformer platform features a 2D adjustable slide with ±25 mm manual adjustment in both X and Y directions, controlled from the front of the machine. Stainless steel transmission shafts prevent rust, with position digital displays and locking functions.

Workpiece Transfer Manipulator

Between the internal cavity and spline stations, synchronous grippers move workpieces in multiple directions, driven by servo motors and pneumatic components. Three sets of grippers transfer parts between stations in a step sequence before returning to the starting position.

Spline Station

The upper center adopts a pneumatic elastic clamping spring to compensate for thermal expansion, with motor-driven adjustment for different workpiece heights. Rotation speed is digitally adjustable. Fixtures are stainless steel with quick-change capability.

Auxiliary Cooling

An auxiliary spray cooling function is provided at the spline quenching station before the next process stage.

Defective Part Rejection

Defective workpieces are pushed into a locked rejection channel, accessible only by authorized personnel. If more than three defective alarms occur consecutively, the induction heating machine pauses automatically for operator confirmation. All defective parts are recorded in the data system.

Lubrication

Automatic centralized lubrication with adjustable distributors delivers oil to guide rails, ball screws, and bearings. End-point pressure sensors monitor supply status.

Quenching Fluid Recovery

The quenching tank is separate from the machine for easy maintenance. Fluid passes through a magnetic filter and paper-band filter, with pressure switches for clogging alarms.

Machine Enclosure

Stainless steel panels and tempered glass sliding doors enclose the quenching area, allowing real-time observation. A fully enclosed design with top piping interfaces and oil-water collection ensures cleanliness.

Additional Features

Anti-collision protection for the inductor.

Length detection at the spline quenching station.

Protective measures for all moving parts in the quenching zone.

Custom exterior color coating.

Flow switches on the inductor and transformer return lines for water monitoring and alarms.

Electrical Control System

The control system of the induction heating machine uses the Siemens 828D CNC, managing both machine and cooling systems. The interface allows both automatic CNC operation and manual mode, with storage for at least 200 part programs. The quality monitoring system communicates with CNC to record parameters such as voltage, current, power, energy, frequency, water temperature, flow rate, and rotation speed.

Key features include:

Servo-driven manipulators with digital speed/position control.

CNC-controlled spraying with real-time flow monitoring.

Independent power control for each station, with alarm functions.

Parameter inputs via dedicated CNC HMI screens.

Multilevel user permissions and error-prevention input validation.

Mechanical and electrical protections for safe operation.

The induction heating machine not only ensures precision and consistency in quenching processes but also integrates advanced automation, monitoring, and safety systems. With its robust mechanical design, efficient fluid management, and user-friendly CNC interface, it represents a modern, high-performance solution for industrial heat treatment applications. By combining Siemens automation, corrosion-resistant materials, and precision motion control, the induction heating machine maximizes production efficiency while reducing operator workload.

For manufacturers seeking reliability, adaptability, and advanced process control, the induction heating machine is an essential investment in sustainable and high-quality production.