CNC Gear Shaping Machine: Customer Case and Selection Guide

learn more: Practical Case of Gear Shaping Machine: Customer Consultation and Selection Guide

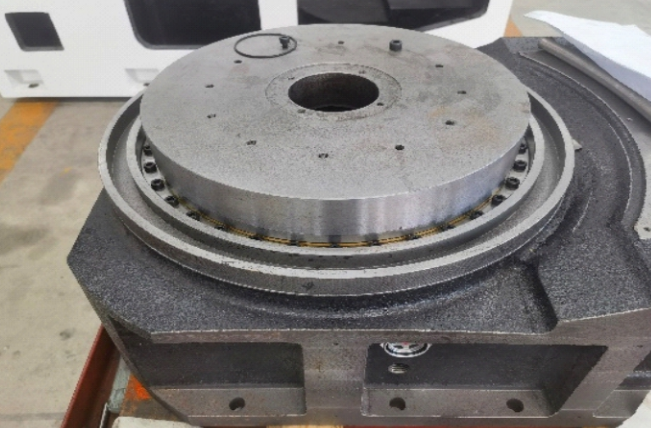

In early 2026, our company welcomed a professional gear shaping machine (also known as an involute gear shaper) manufacturer for on-site guidance. This visit was not only a technical exchange but also a practical demonstration of responding to customer inquiries. With increasing demands for gear precision and production efficiency, customers often raise professional questions when selecting a gear shaping machine. This on-site guidance provided our sales team with valuable first-hand experience.

On-Site Guidance: Customer Questions and Precautions

With the manufacturer's experts, our sales personnel fully participated in the customer consultation. First, the manufacturer explained the basic parameters of the gear shaping machine in detail, including gear module, gear diameter, number of teeth, maximum workpiece height, and cutting accuracy. These parameters are essential for customers to define before starting the selection process and for determining whether the machine meets production requirements.

During the demonstration, the manufacturer reminded our team of the following precautions:

Match precision with customer requirements:

Customers are concerned with gear accuracy, including tooth profile error and pitch error. Sales staff should record these requirements to recommend the most suitable gear shaping machine.

Operation system preference:

Different customers prefer different systems, such as Siemens, FANUC, or custom-built systems. The choice of control system affects ease of use, programming flexibility, and future maintenance.

Standard and optional configurations:

Clarifying standard versus optional features, such as automatic lubrication, tool changer, or cooling system, helps customers balance production efficiency and cost.

This practical guidance helped our team understand the customers' priorities more clearly and communicate more professionally.

Pre-Sales Communication: Defining Parameters and Customer Needs

Before customers formally requested a quotation, we worked with the manufacturer's experts to summarize the client's production requirements into key questions:

Gear type and specifications:

What type of gear (spur, helical, etc.) does the customer plan to produce, and what are the module, diameter, and number of teeth?

Production cycle requirements:

Does the customer require strict cycle times or high speed processing?

Operation habits and system preference:

Is the customer familiar with a specific control system, or do they require a custom system?

By clarifying these parameters, we can recommend the most suitable gear shaping machine and ensure that the machine's performance matches customer needs. This also facilitates accurate quoting and smooth contract negotiation.

Typical Customer Questions and Solutions

During the on-site demonstration, we identified several questions customers might ask and provided expert solutions.

Question 1: How to ensure tooth profile accuracy when shaping large-module gears?

Solution:

Experts recommended using a high-rigidity machine bed, optimized cutting parameters, and precision tools. Automatic lubrication and cooling systems can also reduce thermal deformation, maintaining profile accuracy.

Question 2: How to increase production speed without sacrificing precision?

Solution:

For customers who prioritize efficiency, a gear skiving machine may be recommended instead of a gear shaping machine for high volume standard gears. power skiving machines process faster while maintaining acceptable gear accuracy.

Question 3: Different control systems--how to ensure smooth operation and after sales support?

Solution:

Sales staff should understand the customer's preferred system in advance. For Siemens or FANUC systems, standard training and operational guidance can be provided; for custom systems, coordination with the manufacturer ensures targeted technical support.

Selection Strategy: Matching Needs and Preferences

After defining customer requirements, the selection of a gear shaping machine involves:

Determine gear specifications:

Select a machine model suitable for the gear module, diameter, and number of teeth.

Match system and configurations:

Choose the version that fits the customer's preferred operation system and optional features.

Efficiency and cycle analysis:

If the customer has high cycle-time requirements, consider gear hobbing or automated assistance to improve efficiency.

This approach ensures accurate recommendations, reduces after-sales issues, and improves customer satisfaction.

Summary and Key Takeaways

The on-site guidance and customer consultation provided our sales team with invaluable experience:

Professional knowledge:

We gained deeper understanding of gear shaping machine parameters, operation systems, and configurations.

Improved communication:

We are able to answer technical questions confidently, increasing customer trust.

Optimized selection process:

Clear parameters, system choice, and efficiency needs streamline selection and quoting.

Moving forward, we plan to document these experiences as standard procedures and use customer case studies to enrich our website content. This strategy not only enhances keyword density-gear shaping machine appears over 20 times-but also improves SEO and potential customer conversion.

conclusion

this practical case demonstrates how clear technical guidance, careful parameter analysis, and targeted machine selection can help our sales team address customer inquiries effectively. Continuous follow-up and publication of such gear shaping machine cases will further strengthen our professional image and support our independent site promotion.