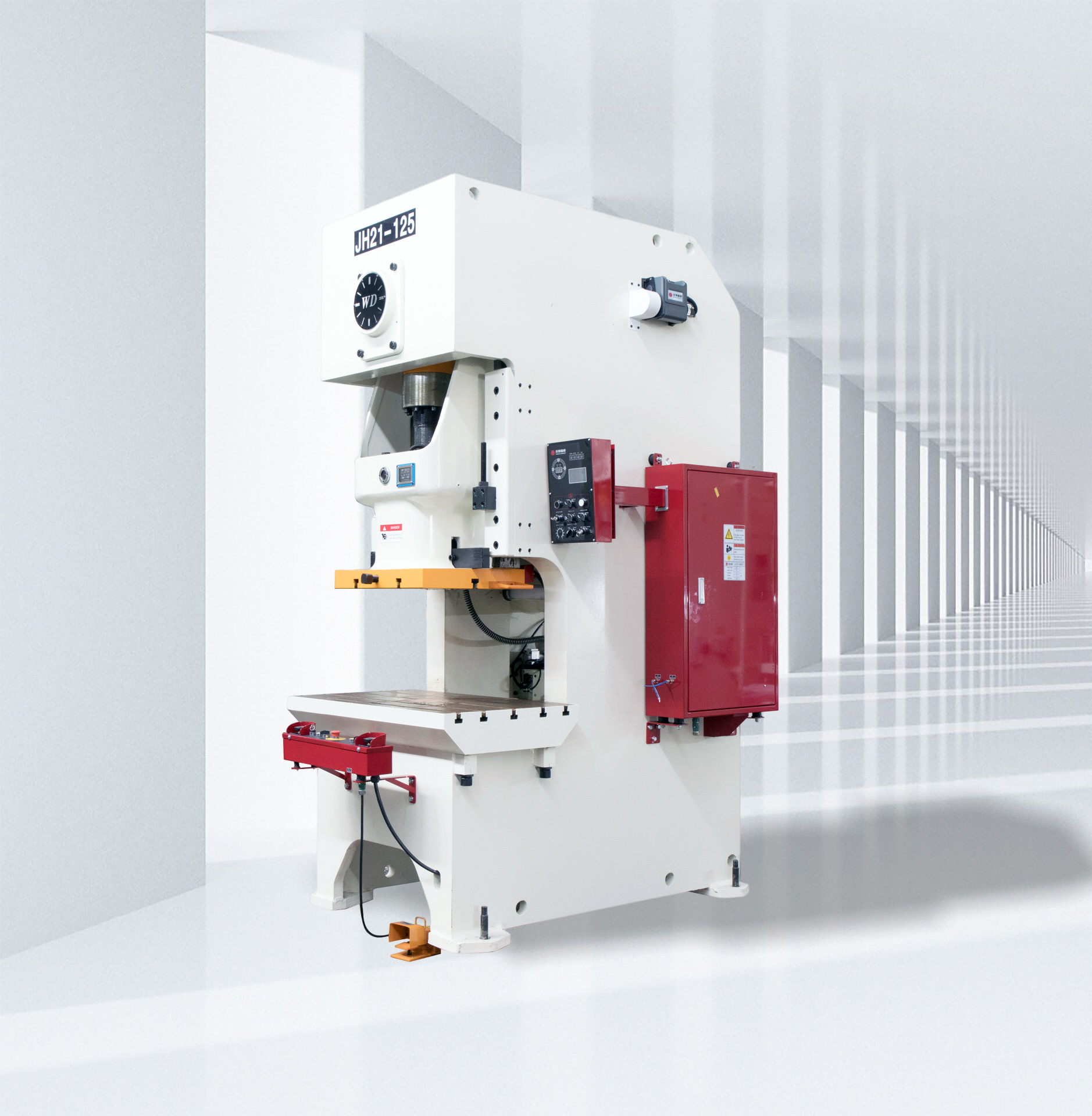

Stock C-Type Stamping Power Press Machine ffor Sheet Metal Hole Punching Machine

Stock C-Type Stamping Power Press Machine ffor Sheet Metal Hole Punching Machine

● Nominal Pressure:25ton-400ton

● Stamping Parts:Aluminum, phosphor bronze,stainless steel,steel,alloy,copper,plastic etc

● Forming way:Punching, blanking, bending, burning, deep drawing, forming, etc

JH21 Series Power press is a C frame mechanical press machine which is widely used for sheet metal stamping, piercing, trimming and bending process.This power press machine could work with single punch die and progressive die.This mahine mainly produce home appliance parts, tv brackets, auto parts, utensils and similar stamping parts.The JH21 power press machine can build an automatic press line with NC feeder decoiler system.

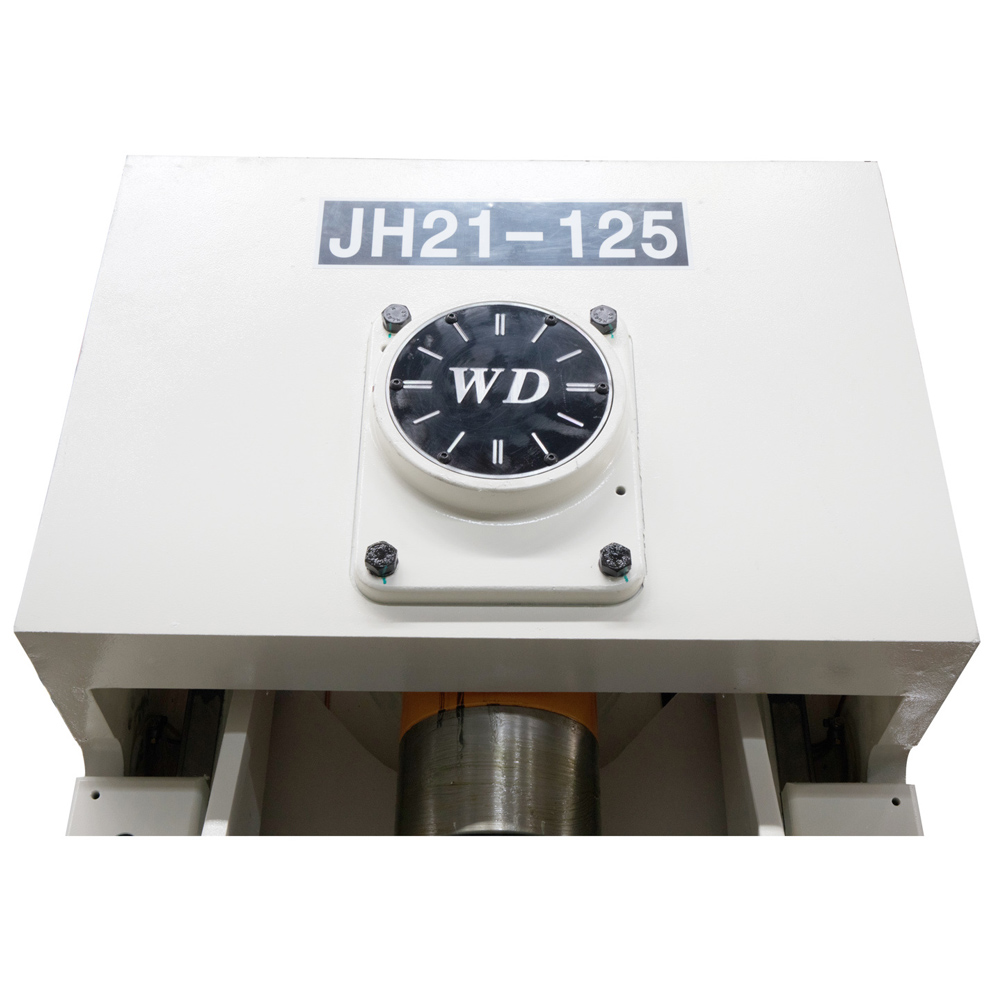

1.Steel welded body, tempering treatment or VSR(Vibratory Stress Relief), high rigidity, accuracy and stability;

2.Pneumatic dual balance cylinders, which balance the slide and punch weight to reduce noise and impact;

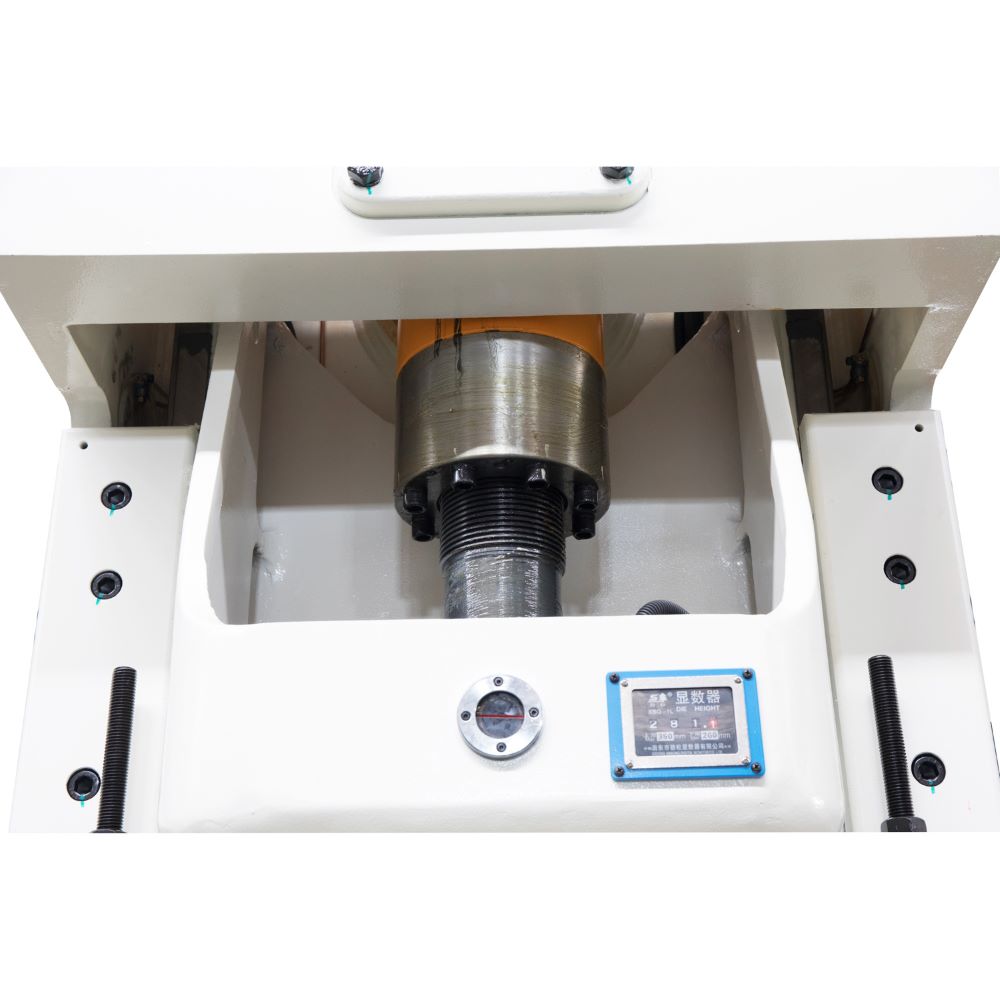

3.The crankshaft undergoes gringding treatment after high frequency quenching;

4.Lengthened six-face rectangle guide with a surface of bronze plate;

5.Vertical located crankshaft, compact structure;

6.PLC control and imported safety duplex valve;

7.Wet type combined multi discs friction clutch and brake;Hydraulic overload protecting pump.

Parameter | Unit | JH21-25 | JH21-60 | JH21-80 | JH21-100 | JH21-125 | JH21-200 | JH21-315 | ||

Nominal Capacity | KN | 250 | 600 | 800 | 1000 | 1250 | 2000 | 3150 | ||

Nominal Stroke | mm | 3 | 4 | 5 | 5 | 6 | 6 | 7 | ||

Slide Stroke Length | S | mm | 80 | 140 | 160 | 160 | 180 | 220 | 220 | |

Slide Stroke | Fixed | S | times | 100 | 70 | 60 | 55 | 50 | 45 | 30 |

Variable | S | times | 60-120 | 45-85 | 40-75 | 35-65 | 35-60 | 30-55 | 20-35 | |

Max. Die Set Height | S | mm | 250 | 300 | 320 | 335 | 350 | 450 | 500 | |

Die Height Adjustment | mm | 50 | 70 | 80 | 90 | 90 | 110 | 120 | ||

Throat Depth | mm | 210 | 270 | 310 | 330 | 350 | 430 | 450 | ||

Distance Between Uprights | mm | 450 | 560 | 610 | 670 | 670 | 910 | 980 | ||

Slide Bottom Size | L x R | mm | 360 | 480 | 540 | 620 | 620 | 880 | 950 | |

F x B | mm | 250 | 400 | 460 | 520 | 520 | 650 | 700 | ||

Handle Hole Size | Dia | mm | 40 | 50 | 50 | 70 | 70 | 70 | 70 | |

Depth | mm | 65 | 70 | 65 | 90 | 90 | 100 | 130 | ||

Bolster Size | L x R | mm | 720 | 930 | 950 | 1060 | 1100 | 1390 | 1540 | |

F x B | mm | 400 | 520 | 600 | 640 | 680 | 840 | 880 | ||

Bolster Thickness | mm | 80 | 130 | 140 | 145 | 155 | 180 | 190 | ||

Table Hole Diameter | mm | 150 | 150 | 180 | 180 | 200 | 240 | 260 | ||

Bolster Surface Height | mm | 780 | 900 | 900 | 900 | 900 | 1000 | 1000 | ||

Overall Size | F x B | mm | 1500 | 1540 | 1765 | 2000 | 2040 | 2600 | 2720 | |

L x R | mm | 945 | 1200 | 1200 | 1300 | 1320 | 1540 | 1680 | ||

H | mm | 2120 | 2570 | 2725 | 3010 | 3035 | 3800 | 3850 | ||

Distance between | F x B | mm | 980 | 1100 | 1210 | 1365 | 1430 | 2020 | 2140 | |

L x R | mm | 690 | 840 | 920 | 1020 | 1040 | 1360 | 1500 | ||

Motor Power | Kw | 3 | 5.5 | 7.5 | 7.5 | 11 | 18.5 | 30 | ||

Weight | Kg | 2450 | 5150 | 6450 | 8650 | 9550 | 19200 | 26600 | ||

Press Pressure | Mpa | 0.5 | ||||||||

Δ How to choose equipments?

This guide will help you to choose the best press machine equipments for your project. Use this handy reference table to compare the facts. Quickly see the difference in standard or optional equipments. Make an informed decision so you know what you are buying. However, these equipments are ever-changing, with new models or capabilities being added all the time.

Standard Equipments | |||

Wet clutch(World) | Hydraulic overload protecting pump | Auto lubrication system | Manual lubrication system |

Joint for miss-feeding | Balance cylinders for slide and upper die | Touch screen | Cam controller |

Air source quick connector | Electronic crankshaft angle indicator(JH21-25~80 with pointer) | PLC : Programmable logical controller | Shock Absorption Pads |

Working lamp | Die height adjusted motor(JH21- 60~400) | Air blowing | Second degree drop |

Preset counter (Touch screen display) | |||

Optional Equipments | |||

Dry clutch | Air cushion apparatus | Die quick change device | Light curtain Protection |

Foot pedal | Output shaft | Requency control | Slider mold handle hole(JH21-100~JH21-400) |

Stripping device | |||

1.What are your normal lead times?

Normally, 30 to 60 days

2.What kind of package do you offer?

Standard wooden case packing

3.Do you have certification of your machine?

CE certificate

4.How about the warranty service?

24 months

5.How about the installation and commissioning?

we will enclose the production specification with the machine, and we could provide the video online to you, and our engineers are available to debug machinery overseas.

6.How to select the suitable machine?

Pls tell us the machine you need, Includes drawings, specifications and other requirements.

7.How to do it if we meet the issue during the operation?

We provide completely after sales service, and our engineers are available to service machinery overseas.

8.If we want to learn how to operate the machine, Can you provide it?

Yes, we have special service team which will offer you professional guidance.