Vertical Induction Hardening Quenching Heating Heat Treatment Machine

Vertical Induction Hardening Quenching Heating Heat Treatment Machine

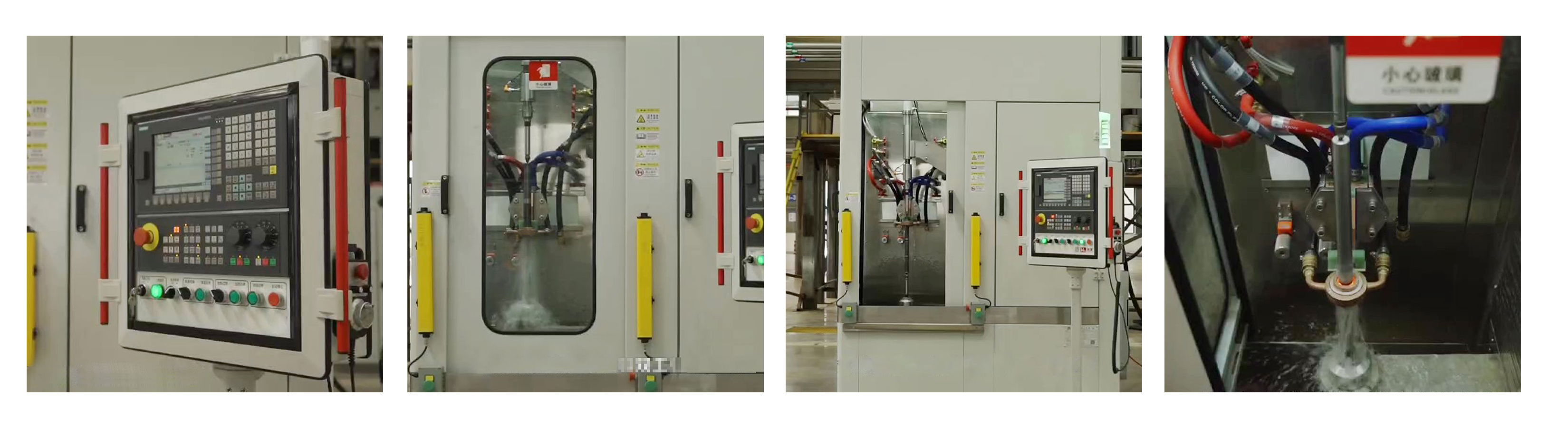

Intelligent CNC and Data Management

Advanced CNC System Control: Equipped with a dedicated parameter management, monitoring, and recording system, this feature enables precise documentation of quenching process parameters and easy access to historical data queries. Ensuring every batch meets stringent quality standards, it supports full traceability and enhances production management.

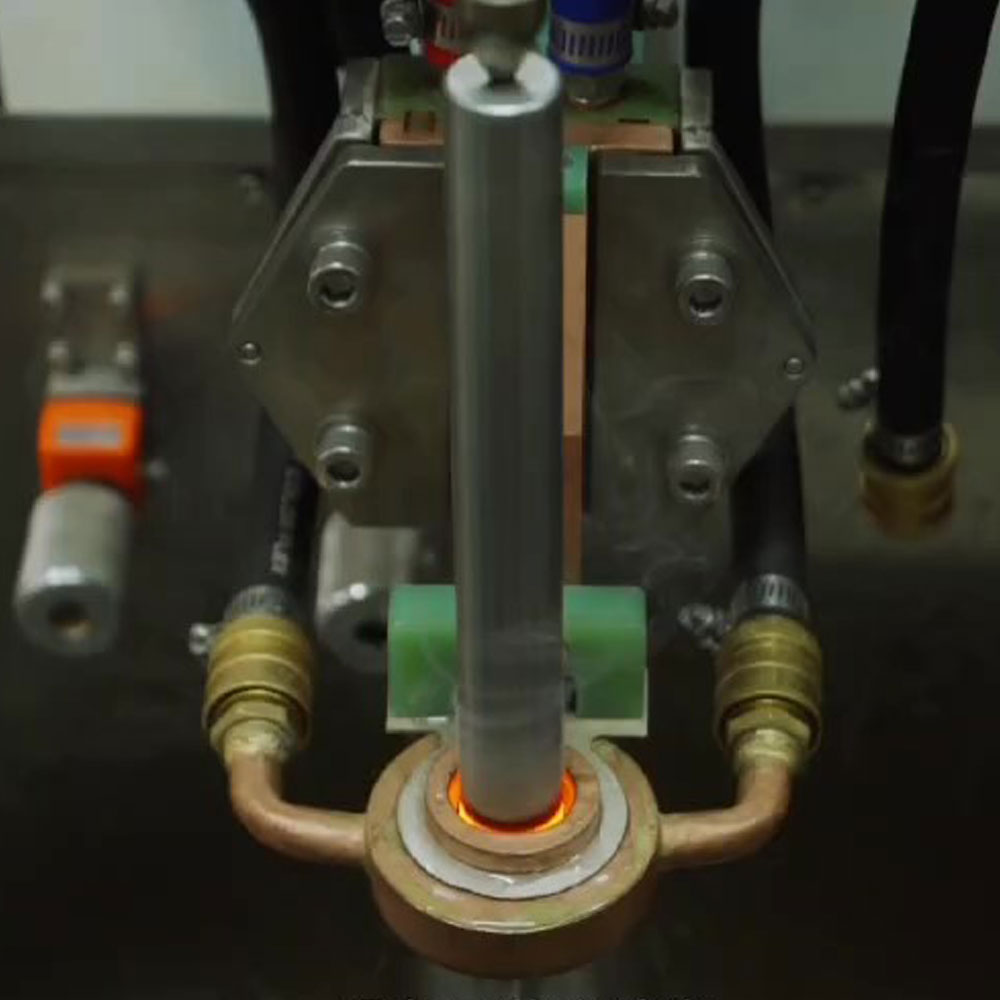

Efficient Modular Design and Stable Performance

Digital Transistor Induction Heating Power Supply and Modular Layout: The machine features a stable digital transistor induction heating power supply with comprehensive protective functions and reliable performance. The modular design allows for efficient completion of induction hardening tasks on various parts, adapting to diverse production needs and significantly improving production efficiency and flexibility.

Q: What is the warranty period?

A: We offer a warranty service for all purchased products ranging from 12 to 24 months, ensuring you are worry-free during the use of our equipment. Choosing us means choosing a long-term and reliable partner.

Q: What is the delivery time?

A: For in-stock items, we guarantee delivery within 1-2 months; for custom-manufactured products, we commit to delivering within 5-6 months. No matter how urgent your needs are, we can respond quickly to ensure your project proceeds on schedule.

Q: Do you provide after-sales service?

A: Yes, we provide comprehensive after-sales services, including but not limited to timely supply of spare parts, online technical support, on-site installation and commissioning, as well as operational training. We strive to offer you the most thoughtful service support to ensure the efficient operation of equipment and assist in the continuous growth of your business.

Q: What additional products or services do you offer?

A: we also provide "turnkey" engineering services, customizing automated production lines according to customer needs to ensure seamless integration with existing production processes. We are committed to offering complete solutions to every customer, helping you achieve maximum production efficiency.