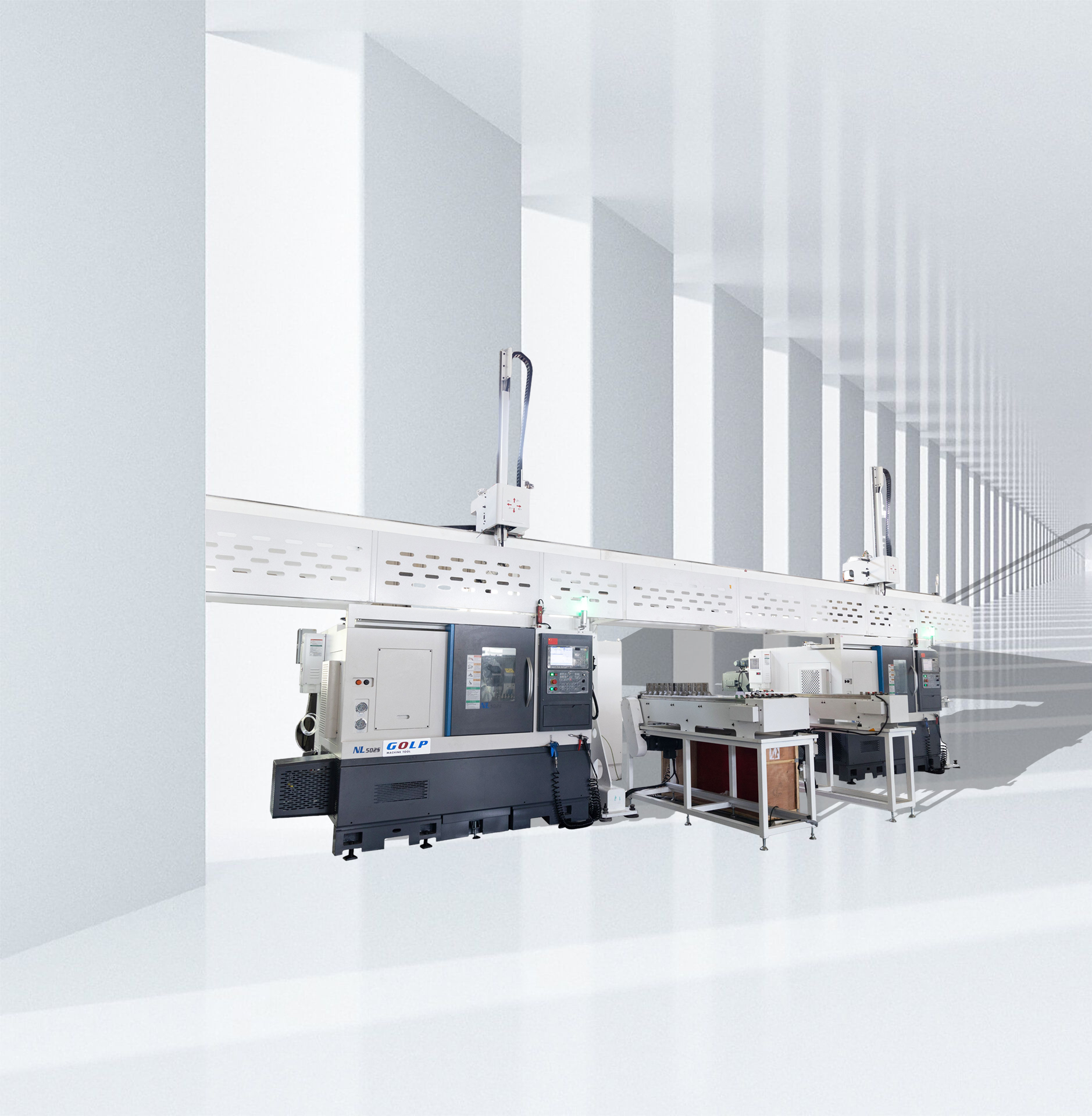

automation trusss manipulator cnc turning machine

automation trusss manipulator cnc turning machine

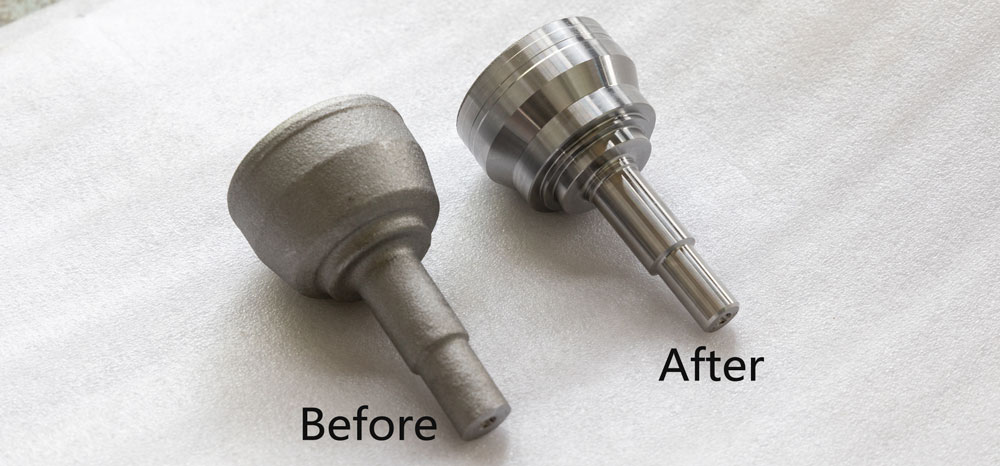

1. High precision: the automated cnc turning machine adopts CNC technology, which can realize very high machining precision, which is especially important for such parts as bell-shaped shells that require precise dimensional control.

2. Good surface quality: through fine adjustment of cutting parameters and selection of suitable tool materials, good surface finish can be obtained to meet high quality requirements.

High productivity: automated cnc turning machine can work continuously and realize automated operation in tool changing, loading and unloading, etc., which improves the productivity.

3. Good consistency: As the whole machining process is controlled by the program, the machining of each bell-shaped shell follows the same process, so the consistency and interchangeability of the products are very high.

4. Strong adaptability: for different specifications or types of bell-type shells, only need to change the corresponding processing program can be quickly switched to the production task, suitable for small quantities of multi-variety production mode.

5. Reduced manual intervention: a high degree of automation means less reliance on skilled labor and reduced quality fluctuations due to human factors.

Q: What is the warranty period?

A: We offer a warranty service for all purchased products ranging from 12 to 24 months, ensuring you are worry-free during the use of our equipment. Choosing us means choosing a long-term and reliable partner.

Q: What is the delivery time?

A: For in-stock items, we guarantee delivery within 1-2 months; for custom-manufactured products, we commit to delivering within 5-6 months. No matter how urgent your needs are, we can respond quickly to ensure your project proceeds on schedule.

Q: Do you provide after-sales service?

A: Yes, we provide comprehensive after-sales services, including but not limited to timely supply of spare parts, online technical support, on-site installation and commissioning, as well as operational training. We strive to offer you the most thoughtful service support to ensure the efficient operation of equipment and assist in the continuous growth of your business.

Q: What additional products or services do you offer?

A: we also provide "turnkey" engineering services, customizing automated production lines according to customer needs to ensure seamless integration with existing production processes. We are committed to offering complete solutions to every customer, helping you achieve maximum production efficiency.