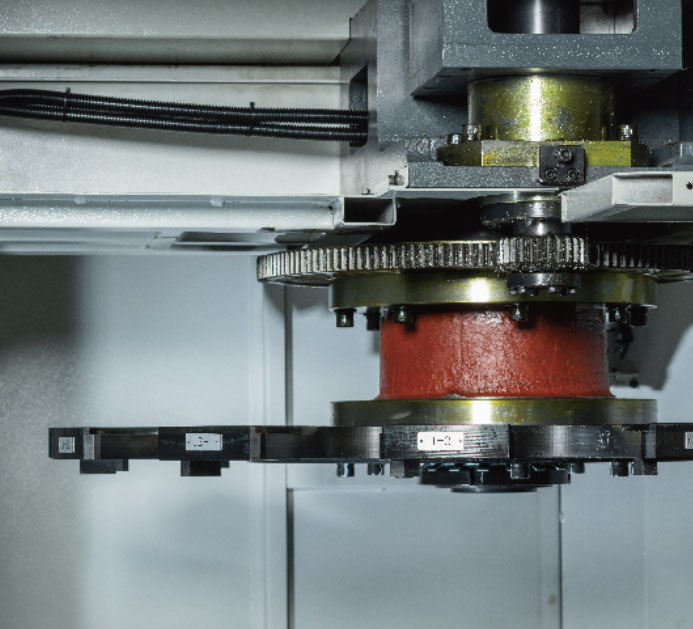

CNC Single Column Mobile Vertical Machining Centre Lathe for Gear/Ring Processing

CNC Single Column Mobile Vertical Machining Centre Lathe for Gear/Ring Processing

High Precision, High Rigidity, High Stability, Heavy Cutting, High Efficiency

Diameters ranging: 1 to 3 meters.

A:The column is designed with an integrated box structure, and configured with largespan and wide hard rail contact surface, with small vibration and high stability

B: Designed with a lifting crossbeam and hydraulic locking mechanism, it is easy to operate and has strong maneuverability in machining range as well as a simple

structure;

C: The workbench adopts TIMKEN cross roller bearings from US to ensure that the spindle has high radial and axial bearing capacity at high and low speed, so as to achieve high precision, low noise and durability;

D: With high output power, drilling and milling accessories and CF axis control, it shows multifunctions of one machine, such as turning, milling, drilling and tapping.

Standard machinery specifica | Unit | SZ1000ATC | SZ1200ATC | SZ1600ATC | |

Machinery capability/capacity | |||||

Discface diameter | mm | ø1000 | ø1250 | ø1600 | |

Maximum rotation diameter | mm | ø1350 | ø1600 | ø2000 | |

Maximum cutting diameter | mm | ø1100 | ø1400 | ø1800 | |

Maximum cutting height | mm | 900 | 1200 | 1200 | |

Maxumum weight of machined object | kg | 4000 | 5000 | 8000 | |

Amount of movement | |||||

Left and right(X-axis)stroke | mm | ‐400,+720 | ‐600,+875 | ‐100,+1125 | |

Up and down (Z-axis)stroke | mm | 800 | 900 | 900 | |

Crossbeam up/down stroke | mm | 500 | 750 | 750 | |

Spindle | |||||

Spindle speed | Low gear | rpm | 1~160 | 1~108 | 1-65 |

High gear | rpm | 160~600 | 108~350 | 65~250 | |

#2Spindle speed | Low gear | rpm | |||

High gear | rpm | ||||

Maximum torque of spindle | N.m(kgf-m) | 8240(840) | 8180(834) | 19,677(2007) | |

Feed speed | |||||

X-axis fast feed | m/min | 12 | 12 | 12 | |

Z-axis fast feed | m/min | 10 | 10 | 10 | |

Cutting feed | mm/min | 1~2000 | 1~2000 | 1~2000 | |

Manual feed | mm/min | 0~6 | 0~6 | 0~6 | |

Automatic tool change device | |||||

Number of tool positions | 12tool positions | 12tool positions | 12tool positions | ||

Shank type | 7/24taperBT-50 | 7/24 taper BT-50 | 7/24 taper BT-50 | 7/24 taper BT-50 | |

Maximum tool size | mm | 2800W×150T×400L | 2800W×150T×400L | 2800W×150T×400L | |

Maximum tool weight | kg | 50 | 50 | 50 | |

Maximum tool magazine capacity | kg | 600 | 600 | 600 | |

Tool change time(tool to tool) | Sec | 40 | 40 | 40 | |

Spindle motor | |||||

(FANUC)Spindle motor(FANUC) | kw | 37/45(α40) | 37/45(α40) | 37/45(α40) | |

#2 spindle motor | kw | ||||

X-axis servo motor | kw | 6(α40i) | 6(α40i) | 6(α40i) | |

Z-axis servo motor | kw | 6(α40iβ) | 6(α40iβ) | 6(α40iβ) | |

CF-axis servo motor | kw | ||||

Motor for cutting fluid pump | kw | 1.5 | 1.5 | 1.5 | |

(SIEMENS)Spindle motor(SIEMENS) | kw | 37/51(1PH7167) | 37/51(1PH7167) | 37/51(1PH7167) | |

#2 spindle motor | kw | ||||

X-axis servo motor | kw | 7.7(1FK7105) | 7.7(1FK7105) | 7.7(1FK7105) | |

Z-axis servo motor | kw | 7.7(1FK7105) | 7.7(1FK7105) | 7.7(1FK7105) | |

CF-axis servo motor | kw | ||||

Motor for cutting fluid pump | kw | 1.5 | 1.5 | 1.5 | |

Tank capacity | |||||

Hydraulic tank | L | 60 | 130 | 130 | |

Cutting fluid tank | L | 750 | 600 | 550 | |

Lubricating oil tank | L | 4.6 | 4.6 | 4.6 | |

Power specifications | AC220±10%.60Hz±5Hz | ||||

Power demand | KVA | 65 | 65 | 65 | |

Machine tool dimennsions(L×W×H) | mm | 4700×3900×4500 | 5050×4170×4760 | 4500×5300×5000 | |

Machine weight approximately | kg | 21,000 | 33,000 | 24,500 | |

Accuracy | mm | Positioning accuracy:±0.007/500 repeated accueracy:±0.005 C-axis positioning accuracy:±7.5”/360° C-axis repeated accueracy:±5” | |||

| ATC+C Type |

| AUTOMATIC TOOL CHANGE SYATEM |

| Full Servo 12T BT50 Tool Magazine Accurate positioning and error-free tool changing; the tool magazine is driven by a servo motor, with fast positioning and high torque. There are four types of tool positions (optional): 24,32,48 and 60. |

| AUTOMATIC TOOL CHANGE SYATEM |

1.What are your normal lead times?

Normally, 30 to 60 days

2.What kind of package do you offer?

Standard wooden case packing

3.Do you have certification of your machine?

CE certificate

4.How about the warranty service?

24 months

5.How about the installation and commissioning?

we will enclose the production specification with the machine, and we could provide the video online to you, and our engineers are available to debug machinery overseas.

6.How to select the suitable machine?

Pls tell us the machine you need, Includes drawings,specifications and other requirements.

7.How to do it if we meet the issue during the operation?

We provide completely after sales service, and our engineers are available to service machinery overseas.

8.If we want to learn how to operate the machine, Can you provide it?

Yes, we have special service team which will offer you professional guidance.