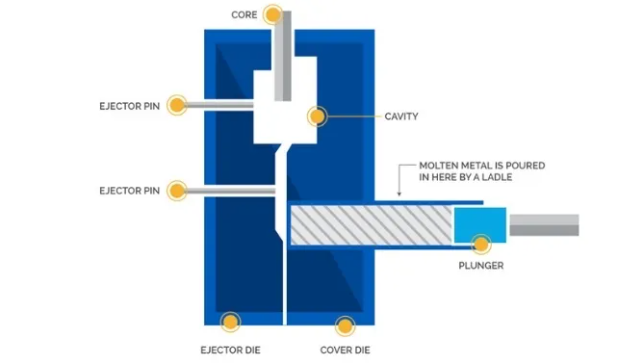

Cold Chamber Die Casting Machine

The cold chamber die-casting manufactured various metals while maintaining high melting points. The metal materials that work with such processes include aluminum, copper, brass, and zinc alloys.

Process of Cold Chamber Die Casting

In the cold chamber die casting process, the metal is molten by heating in the outside equipment furnaces. Next, the molten metal transports into the casting machine and fills the chamber. Using a machine plunger, the molten metal is forced into the mold cavity. The liquid metal is moved to shot sleeves by machine or manually using the ladle. Then there is an injection piston, forcing the molten metal into the die.

Since the cold chamber die casting has a single-shot technique, it helps decrease the connection between the parts’ injector and hot metals. Plus, this process helps heighten the operating life and machine parts'efficiency.

Advantages of Cold Chamber Die Casting

Here are some advantages of using the cold chamber die casting method for component production.

1. Durable & Robust Parts: Cold chamber die casting produces robust and durable metal components while improving visual appeal.

2. Economical Process: This simple process is functional and saves costs. It helps make various components than other techniques.

3. Improved Strength: The mentioned process creates stronger components with accurate dimensions.

4. Precise Dimension: This process creates parts'dimension stability with great tolerance.

5. Easy to Assemble: Cold chamber die casting also forms fastening elements, like bosses, studs, carved holes, and casted threads.

6. Excellent Finishing: This die casting technique produces smoother and textured components'finishes.