Helical gear 、Spur gear 、worm gear

Helical gear is a kind of cylindrical gear with helical teeth. Compared with spur gears, helical gears have the advantages of smooth transmission, good meshing performance, high degree of overlap, high gear strength, silence, low vibration and so on. And can transmit high power.

Helical gears differ from spur gears in that they have helical tooth lines and generate axial collinear forces. The thrust can be eliminated by collimating bearings or by combining left and right helical gears into a herringbone gear. A meshing pair of helical gears must have the same helix angle and opposite helix direction.

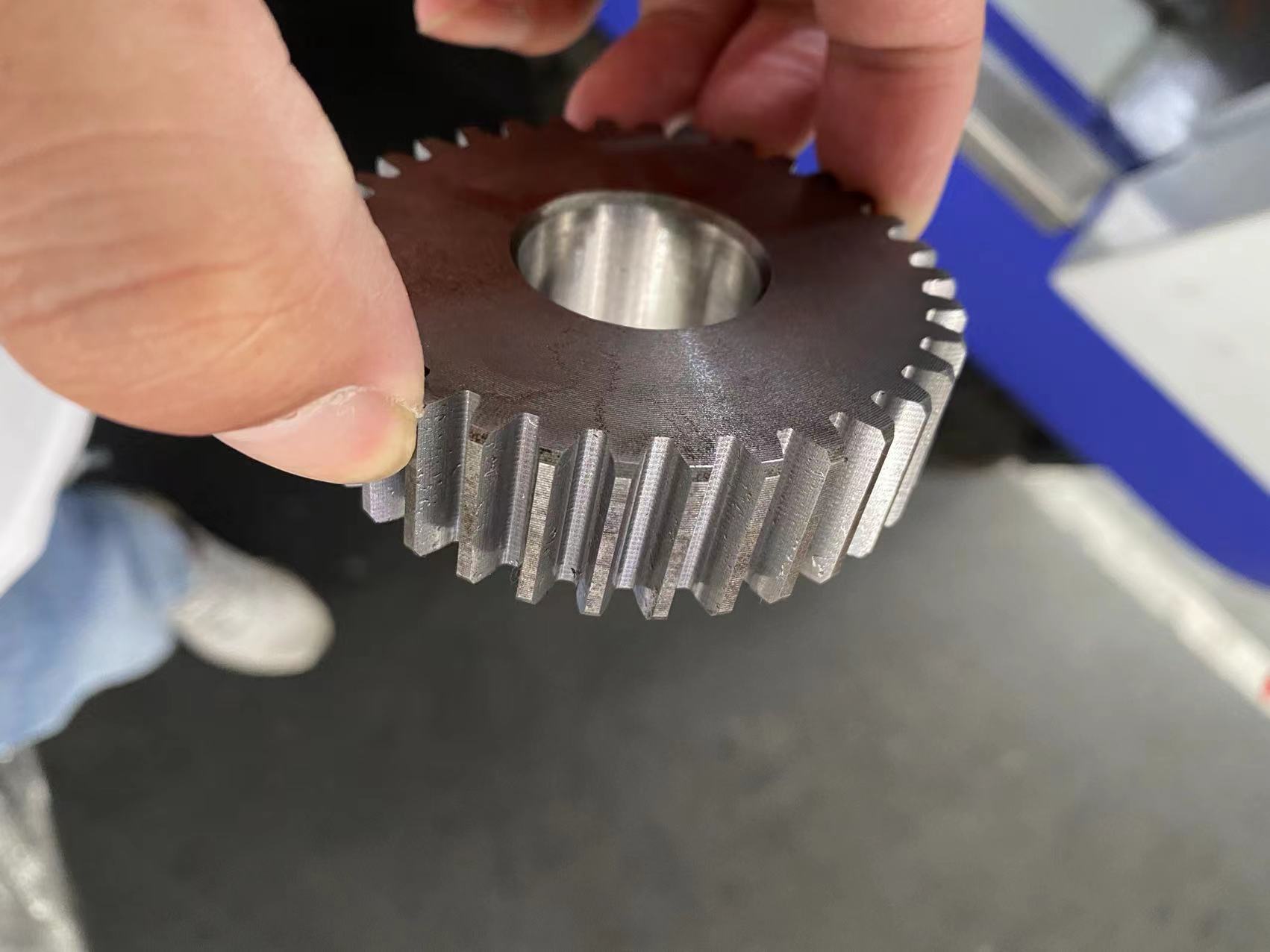

Spur gearing relies on the meshing of the master and follower gears to transmit motion and power. This is a gear driven between two parallel shafts. Straight circular gears are easy to machine, produce high-precision gears, and do not generate thrust (axial force) in the transmission, making them one of the most common gears in actual production and use.

Gear transmission has the advantages of reliable operation, constant ratio, high efficiency, the ability to transfer motion between any two axes in space, and wide adaptability.

Precision worm gear transmission belongs to one kind of gear transmission, which is composed of worm and worm wheel. The worm drives the worm wheel, and the mechanism is usually used to transfer motion and power between two staggered shafts.