90 degree angle milling head in 5-axis machining centers to undertake what work

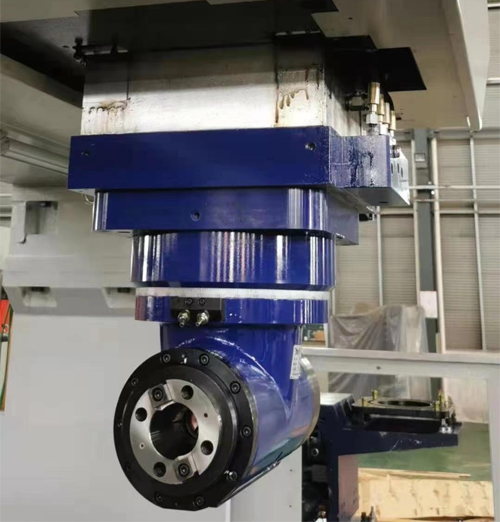

A 90 degree angle milling head, also known as a transverse milling head or horizontal milling head, is a milling head in which the output axis of the tool is parallel to the horizontal plane. The purpose of its use is to expand the machining range of the machine tool, in some large workpieces or products requiring high precision in the case of a wide range of applications. So, do you know what work the right angle milling head in the five-axis machining center? The following is for you to explain:

Right-angle milling head in the five-axis machining center in the actual application process, due to participate in the five-axis rotation and compensation, so the right-angle milling head length size and the accurate acquisition of angular size is to ensure that the tip point of the tool correctly compensated for the prerequisites.

Angle α is the deviation between the actual and theoretical mounting position of the right-angle milling head. In order to ensure that the five-axis rotation and compensation are correct, it is necessary to ensure that α is equal to zero. The specific zeroing method of angle α is as follows: contact the contact tip of the percentage meter with the outer surface of the tool, move the machine spindle up and down in the vertical direction using the manual mode of the machine tool, observe the runout value of the percentage meter, adjust the fastening screw on the right-angle milling head and the machine spindle according to the runout value, and angle α is equal to zero when the runout value is zero.

Lc will change in real time according to the different lengths of the installed tools, and it is necessary to obtain the exact value by means of a tool tester. Because the spindle centerline can not be obtained, so the Lc value can not be measured directly, the specific measurement method is as follows: cutting tool installation in the right-angle milling head is completed, the right-angle milling head placed on the tool tester table, so that the right-angle milling head around the spindle centerline for rotation, find the tip position on the tool tester screen, and measure the maximum radius of gyration.