How does a six-axis CNC gear skiving machine work?

Six-axis CNC Gear skiving Machine is a high-end gear processing equipment, which integrates modern mechanical, electronic, control and information technology, and plays an important role in the gear manufacturing industry with its excellent flexibility, high precision and high efficiency.

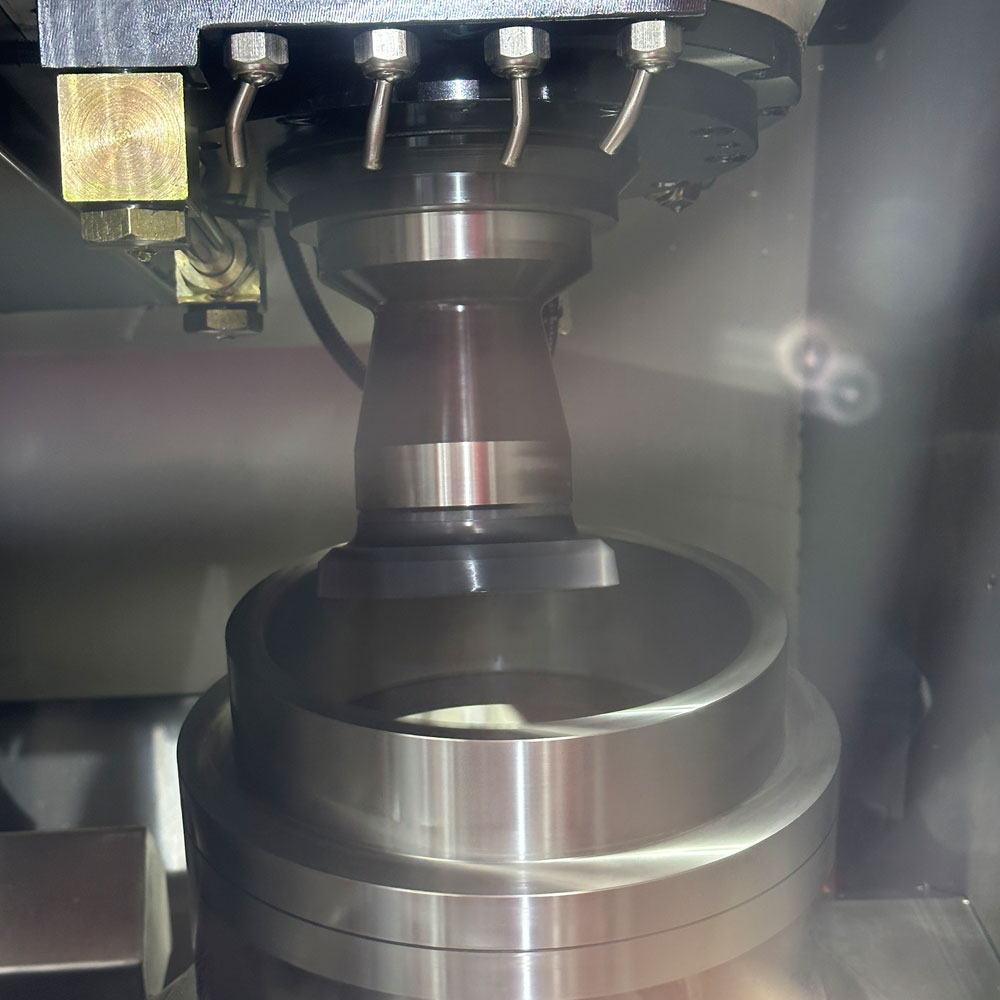

Working Principle

The core of six-axis CNC gear skiving machine lies in its six-axis linkage control system and precision mechanical structure. These six axes usually include three linear axes (X, Y, Z) and three rotary axes (A, B, C), which are able to work together to realize precise control of any angle and position in space. During the machining process, the workpiece is fixed on the table and depth control is achieved by the feed of the Z-axis, while the X and Y-axes are responsible for lateral and longitudinal positioning. The introduction of rotary axes A, B and C allows the machine to machine more complex and variable tooth shapes, such as spiral bevel gears, helical gears and spline shafts.

Machining Workpiece

The 6-axis CNC Gear skiving Machine is capable of machining a wide range of workpiece types, including but not limited to:

1. spiral bevel gears: utilizing its multi-axis linkage capability, bevel gears with complex spirals can be efficiently processed, which is suitable for automotive differentials, heavy-duty mechanical transmission systems, etc.

2. helical gears: for helical gears that require high precision meshing, the 6-axis machine can accurately control the angle and shape of helical teeth to meet the demand for precision transmission.

3. Spline shafts and coupling gears: Whether it is straight or helical spline shafts, or special coupling gears, they can be processed with high quality through their flexible tool paths and precise positioning.

4. Non-standard shaped gears: in the fields of aerospace, precision instruments, etc., it is able to deal with various non-standard and difficult tooth designs to meet specific engineering requirements.

Application Fields

1. automobile manufacturing: automobile transmission, differential and other components use a large number of complex gears, six-axis gear skiving machine is the key equipment to ensure high efficiency, low noise and long life of these components.

2. Aerospace: High precision and high reliability gears are indispensable in aircraft engines and spacecraft propulsion systems.

3. precision instruments: such as precision clocks and watches, medical equipment in the miniature gear components, need to be extremely high processing accuracy and surface quality, six-axis machine tool precision control capabilities to meet this demand.

4. heavy industry and general machinery: in the heavy machinery, mining machinery, wind power generation and other fields, large and bear high load gear components rely on six-axis gear skiving machine to achieve batch production efficiency.

In short, six-axis CNC gear skiving machines, with their powerful processing capabilities and flexibility, enhance the accuracy and efficiency of gear processing at the same time, but also broaden the degree of freedom of gear design, for many high-tech and precision manufacturing areas to provide strong technical support.