How does a Gear Shaping Machine work? How is it different from a gear skiving machine?

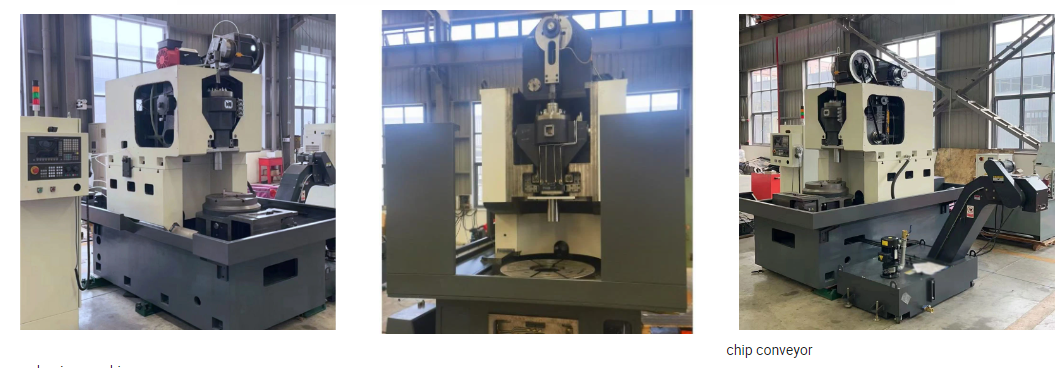

CNC 3-axis Gear Shaping Machine is a highly automated metal cutting equipment, especially in the field of precision machining of gears, splines and other complex shaped parts, plays an important role.

Working Principle

The core of a CNC 3-axis gear shaper lies in the three-dimensional motion system that controls it. It controls the precise linear and rotary movement of the tool (shaper) along the X, Y and Z axes by means of a computerized numerical control (CNC) system. During machining, the workpiece is held stationary while the cutter follows a pre-programmed path, removing material layer by layer along the contour of the workpiece to form the desired tooth shape. This process involves both radial feed (depth of cut) of the tool and continuous or intermittent feed in the axial direction to complete the entire tooth profile.

Machining workpieces

CNC 3-Axis Gear Shaping Machine is widely used in the machining of various kinds of high-precision, complex-shaped internal and external gears and worm gears. It can handle various materials such as cemented carbide, steel, copper, aluminum, etc. It is especially good at applying to the mass production of parts with strict tooth shape accuracy requirements. Whether it is straight, helical or spiral gears, it can realize efficient and high precision machining through precise program control.

Differences between Gear Shaping and Gear skiving

Although gear insertion and gear skiving are both gear machining techniques, there are significant differences in principle and application. Gear skiving usually uses a single-point tool to form the gear tooth shape through continuous cutting motion on the lathe, which is suitable for processing simple straight-toothed cylindrical gears. Gear insertion is the use of multi-tooth tool (gear cutter), through the indexing and insertion action in the workpiece “insert” out of the tooth shape, which makes the gear insertion machine can be more flexible to deal with complex tooth shapes, such as helical, herringbone teeth and internal gears, and in order to ensure high precision at the same time, but also to improve production efficiency and surface finish.

In summary, CNC 3-axis gear shaping machine with its unique processing and wide applicability, in the modern precision machinery manufacturing occupies an important position, especially in the field of gear precision and production efficiency have strict requirements, showing greater advantages.