How does a CNC gear rolling machine work? What are the applications?

The CNC gear rolling machine is a high precision, high efficiency gear processing equipment, which adopts computer numerical control (CNC) technology, can accurately follow the preset program for gear processing. Compared with traditional gear machining methods, the CNC gear rolling machine has higher machining accuracy and faster machining speed, and also greatly reduces the requirements for operator skills.

Principle of operation

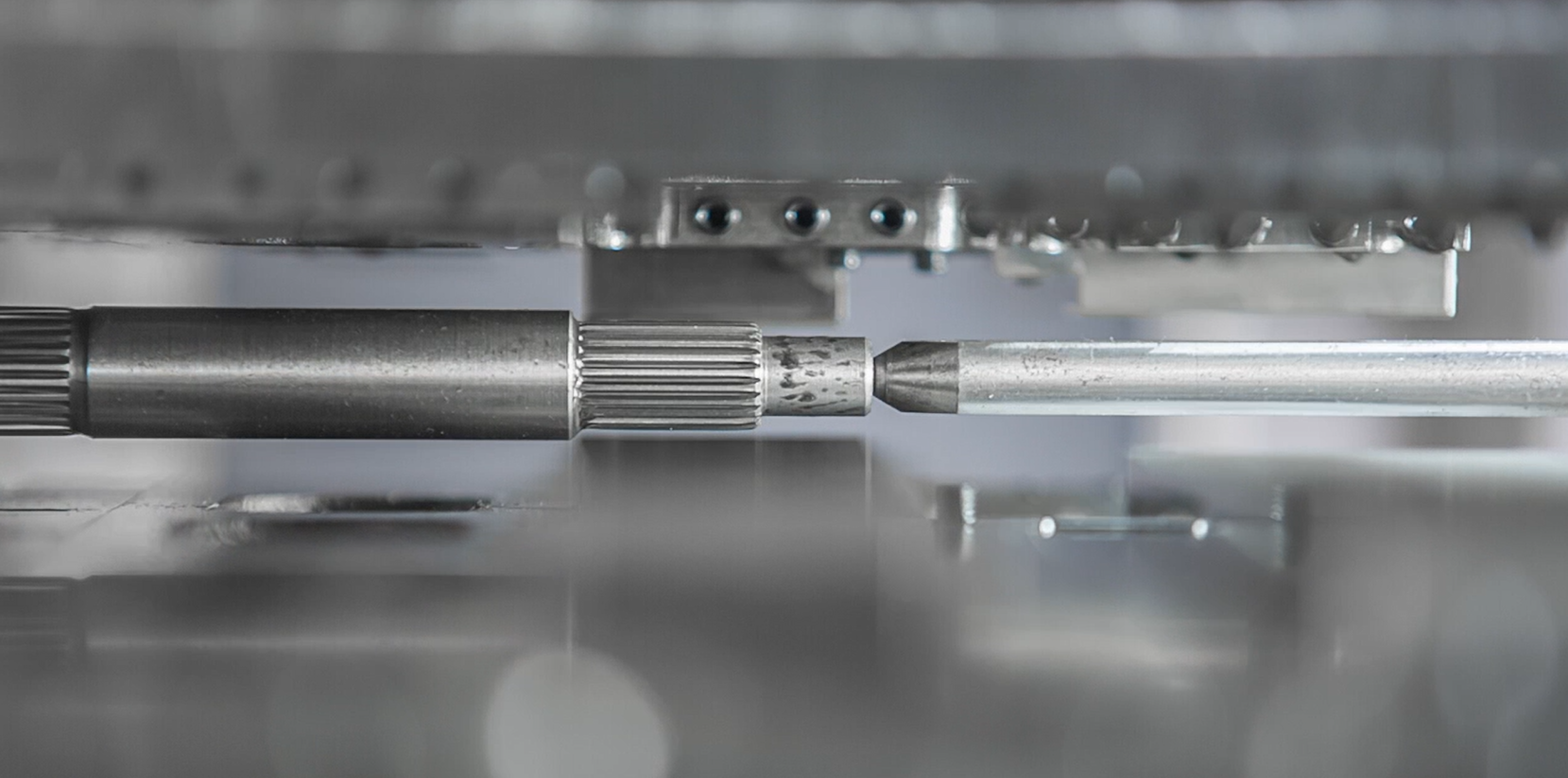

The working principle of the CNC Gear Rolling Machine is to complete the gear molding process by means of two rolling knives rotating in opposite directions. The knives have tooth shapes that match the gears being machined. When the workpiece (gear to be machined) rotates under the spindle, the two knives feed the workpiece from opposite directions and move along the axis of the workpiece, realizing the shaping of the teeth through the relative motion between the knives and the workpiece. This process is usually very fast and a gear can be machined in a few seconds.

Machining efficiency

CNC gear rolling machines are very efficient, mainly due to their high speed and highly automated operation. For high volume production, these machines can significantly increase productivity and reduce labor costs. In addition, due to their high precision, subsequent finishing work is reduced, further increasing overall productivity.

Areas of application

CNC Gear Rolling Machine is widely used in many industries such as automobile manufacturing, aerospace, precision machinery, instrumentation and so on. For example, in the automotive industry, they are used to process various gears in transmissions; in the aerospace field, they are used to manufacture precision gear components in aircraft engines. All of these applications require gears with extremely high precision and reliability, thus placing stringent demands on the machining equipment.

Conclusion

In conclusion, CNC gear rolling machines play an important role in modern manufacturing due to their high efficiency and precision. With the progress of technology, the future of CNC gear rolling machine will be more intelligent, automation, not only can improve production efficiency, but also better meet the needs of different industries on the gear quality is getting higher and higher.