Export of Gear Profile Grinding Machine and Gantry Machining Center to Russia

In the context of increasingly fierce global manufacturing competition, our company successfully exported the YK73100 gear profile grinding machine and the 6920 gantry machining center to Russia. This achievement not only marks an important step in our international market expansion but also demonstrates our outstanding capabilities in the field of high-end machine tool manufacturing.

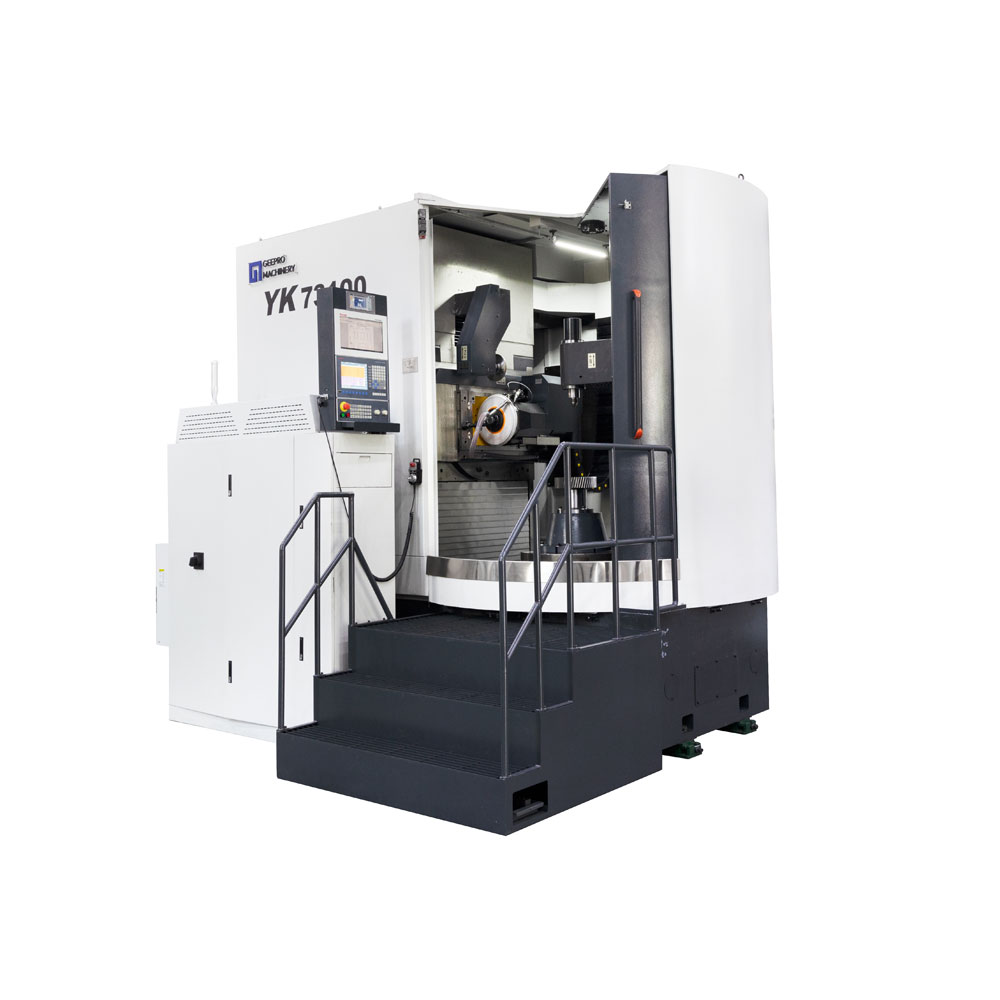

YK73100 Gear Profile Grinding Machine: Gear Processing

High Precision and High Efficiency

The YK73100 gear profile grinding machine is specifically designed to meet the demands of high-precision gear production. Equipped with advanced CNC technology, this machine can achieve extremely precise gear profile grinding. Its main advantages include:

High Precision:

Through a sophisticated control system and high-quality grinding wheels, the YK73100 can perform complex gear grinding within extremely tight tolerances. This level of precision ensures product quality, especially for critical components like gears used in excavator equipment.

High Efficiency:

The optimized cooling system and automatic wheel-changing mechanism significantly improve production efficiency while reducing downtime. This makes the production process smoother and lowers maintenance costs.

Versatility:

The machine is suitable for processing gears of various sizes, from large excavator components to small precision mechanical parts. Its flexibility provides users with more options, adapting to different production requirements.

Practical Applications and Market Impact

In the customer's factory, the YK73100 is primarily used for processing gear components of excavator equipment. These gears are crucial components that directly affect the performance and service life of machinery. The introduction of the YK73100 has significantly improved the quality of the customer's products and enhanced their market competitiveness. Additionally, its efficient production capacity has effectively shortened the production cycle, further enhancing the customer's responsiveness to market demands.

6920 Gantry Machining Center: Energy Industry Applications

Robust Structure and Wide Applications

At the same time, the 6920 gantry machining center was another key product in this export. It is particularly suited for boring and drilling operations, excelling in processing large components such as cylinders used in the energy industry. The main features of this machining center include:

Robust Structure:

With a fixed crossbeam and a movable worktable, the design ensures stability and accuracy during heavy-duty machining. This guarantees high-quality results even under intense operating conditions.

Wide Range of Applications:

Whether it's high-pressure vessels in the oil and gas industry or wind turbine components, the 6920 machining center provides reliable solutions. Its powerful functionality makes it an indispensable tool in the energy sector.

High Degree of Automation:

Equipped with intelligent programming systems and automatic tool changers, complex processes become simpler and faster, significantly shortening production cycles. This intelligent design improves efficiency and reduces the likelihood of human error.

Applications in the Customer's Factory

In the customer's factory, the 6920 gantry machining center is mainly used to process cylinders for the energy industry. By using the 6920, the customer can efficiently complete large-scale component machining tasks, improving overall production efficiency while enhancing product quality.

Customer Recognition and Media Coverage

These two machines have been widely used in the customer's factory and have received high praise. Customers appreciate the machines' high efficiency, reliability, and ease of maintenance. More importantly, the improvements in product quality and production efficiency brought by these machines have given our customers a stronger competitive edge in the market.

Media Reports and Industry Impact

The advantages of these machines have also attracted media attention. Several newspapers reported on their excellent performance and the positive impact they had on customers. Articles highlighted the outstanding contributions of the YK73100 gear profile grinding machine and the 6920 gantry machining center in enhancing the customer's production capabilities.

Looking to the Future

This export not only tested our technical capabilities but also laid a foundation for future international cooperation. We will continue to focus on developing more advanced machine tools to meet the growing needs of the global manufacturing industry. In response to evolving market demands and technological challenges, we plan to introduce more innovative machine tool solutions in the coming years, covering every aspect from design to production.

Technological Advancements and Customer Service

To better serve our customers, we will strengthen cooperation with partners worldwide, exploring new technologies and market opportunities together. Through continuous investment in R&D and service improvements, we aim to help existing customers solve production challenges while attracting new customers to join us.

In conclusion, through this successful export case, we have not only demonstrated our technical capabilities but also contributed to the development of the global manufacturing industry. Moving forward, we will continue to provide higher-level products and services to our customers, working together to create a brighter future.

learn more horizontal gear profile grinding machine