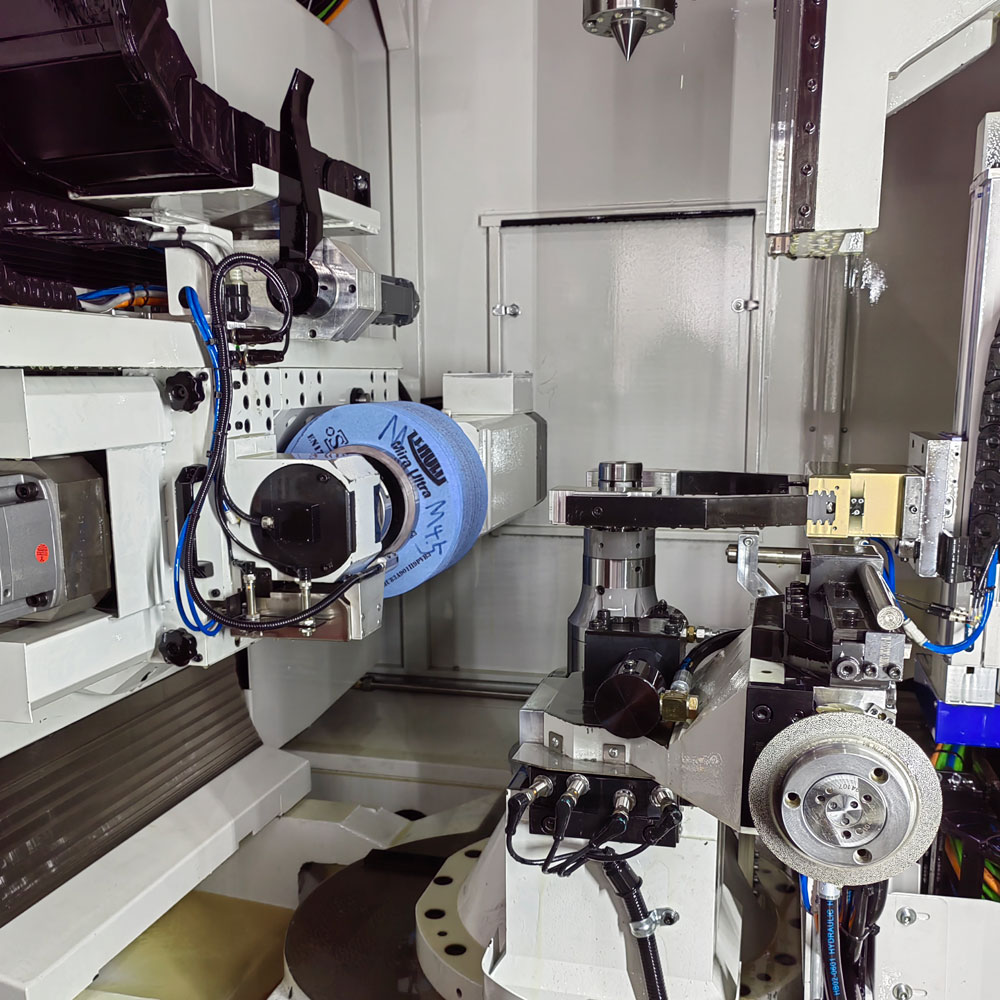

Precision CNC Worm Grinding Machine for cylindrical Gear

Application and Technical Analysis of Worm Grinding Machines

In modern gear manufacturing, the worm grinding machine has become an essential piece of equipment for high efficiency and high precision hard gear finishing. As gears continue to develop toward higher accuracy, better consistency, and mass production, worm grinding machines demonstrate clear advantages in the large scale production of small and medium module gears as well as shaft type gears.

From a process selection perspective, profile grinding machines are more suitable for large gears or multi variety, small batch production. However, for small gears especially in high volume production with strict cycle time requirements-the worm grinding machine is the optimal solution. By adopting the continuous generating grinding principle, the worm grinding machine significantly improves productivity while ensuring excellent gear accuracy.

The Y7232/36CNC CNC worm grinding machine is a representative model developed for these requirements. This worm grinding machine is mainly used for batch production of shaft-type and disc-type hardened cylindrical gears. It can grind involute spur and helical gears, and also supports lead modifications such as crowned and tapered gears. For gears requiring profile modification, the worm grinding machine can be equipped with a dedicated diamond dressing roller to achieve high precision tooth profile control.

In terms of control systems, the worm grinding machine adopts the Siemens 840DSL CNC system, featuring nine CNC axes: tool swivel (A), grinding wheel rotation (B), worktable rotation (C), coolant nozzle rotation (B2), dressing roller rotation (B3), radial feed (X), tangential feed (Y), axial feed (Z), and tailstock vertical movement (W), enabling nine axis five linkage control. This configuration allows the worm grinding machine to excel in complex lead modifications and high-precision synchronous control.

Regarding grinding technology, the worm grinding machine utilizes shifting grinding technology, also known as creep feed grinding. With a grinding wheel spindle speed of up to 7000 rpm and a dressing roller speed of 3000-6000 rpm, the worm grinding machine achieves high efficiency and high-precision grinding, making it ideal for continuous mass production.

On the operational side, the worm grinding machine is deeply customized based on the Siemens 840DSL system. Operators only need to input workpiece, tool, and process parameters through the interface to start grinding, while freely realizing various lead modifications. This highly intelligent operation significantly reduces the skill requirements for machine operators.

In terms of automation, the basic Y7232/36CNC worm grinding machine is equipped with nine CNC axes, while the fully automatic version adds three more axes. When combined with a circulating magazine and automatic loading system, the worm grinding machine can achieve at least one hour of unattended operation, effectively reducing labor intensity and improving overall productivity.

Structurally, the CNC worm grinding machine consists of a machine bed, a main column, and a secondary column. The main column integrates the helix angle swivel unit and grinding head, while the worktable rotation unit is located at the lower side of the secondary column. Both worktable indexing and helix angle rotation are driven directly by torque motors. Together with preloaded cylindrical roller linear guideways, the worm grinding machine features a short transmission chain, high rigidity, and excellent accuracy.

In practical applications, the worm grinding machine offers multiple useful functions, such as displaying the uniformity of grinding allowance on both tooth flanks, automatic allowance balancing, and selectable manual or automatic grinding cycles. Axial movement of the workpiece is controlled by an electro hydraulic proportional valve and high precision linear scale, allowing different feed speeds for each stroke and further enhancing process flexibility.

Moreover, the worm grinding machine has proven its competitiveness in the international market. A Russian customer ordered a fully automated production line equipped with worm grinding machines for shaft gear grinding. During acceptance, the customer conducted strict inspections on machining accuracy, stability, and automation performance, fully confirming the technical advantages of the worm grinding machine in high efficiency mass production.

With its continuous generating grinding principle, high speed and high efficiency grinding capability, CNC system, and mature automation solutions, the worm grinding machine has become a key piece of equipment for modern gear manufacturers pursuing both quality and efficiency. In the future, worm grinding machines will continue to play a vital role in the gear machining industry.

learn more gear profile grinding machines