Your Current Position: NEWS

-

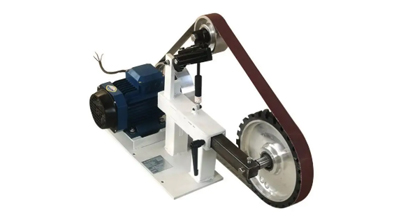

2024-11-20It is a kind of efficient surface treatment equipment, which is widely used in many fields such as metal processing, wood processing, stone processing and so on.

-

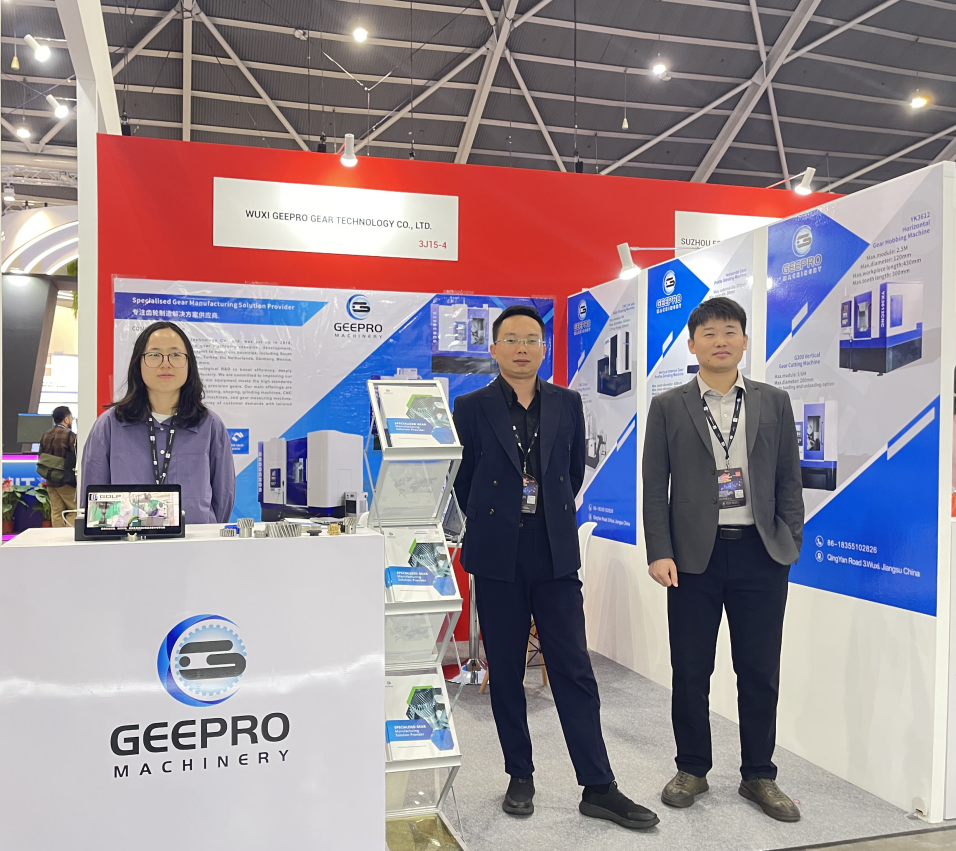

On October 14-16, the 3-day International Exhibition for Industrial Transformation ASIA-PACIFIC (ITAP) in Singapore came to a successful conclusion.

-

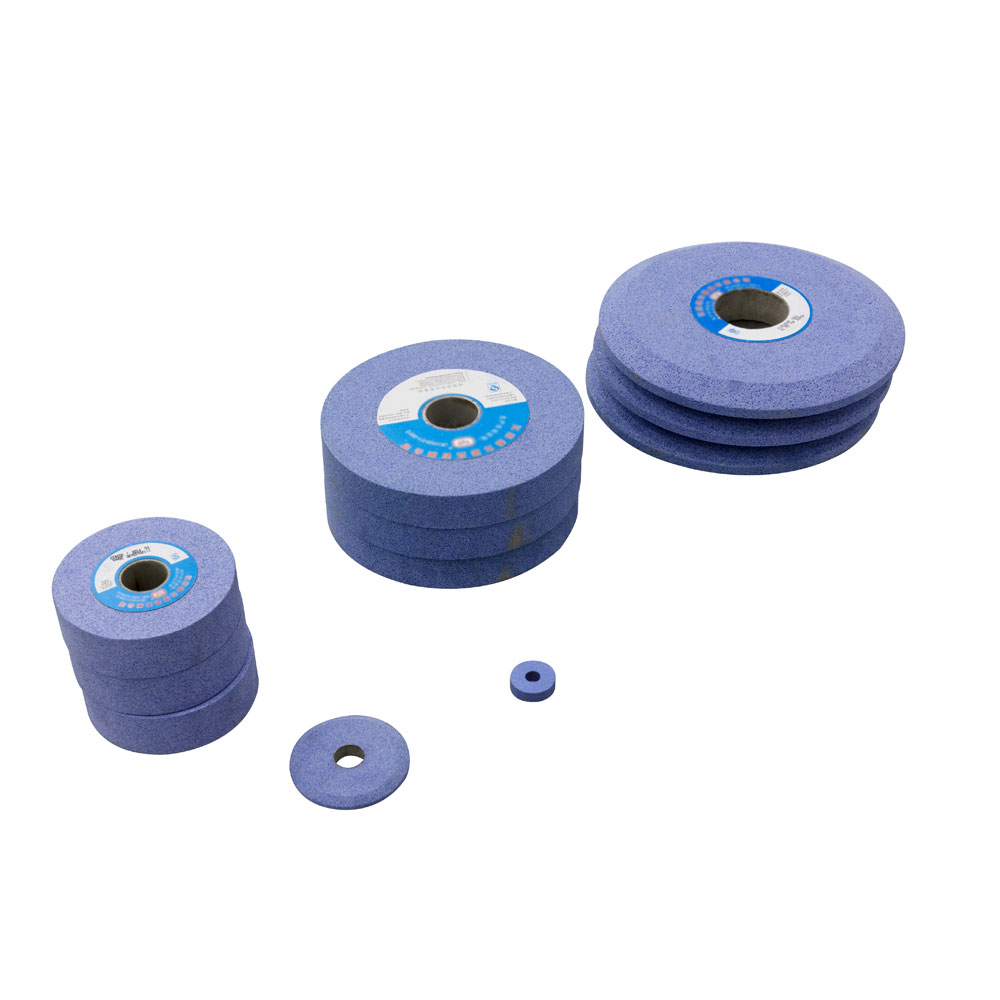

Profile Grinding Wheels are primarily used to machine the surface of a workpiece with a specific profile or shape on a grinding machine.

-

factory stock, yk3612 horizontal gear hobbing machine.contact us.

-

Cold chamber die casting machines are used to produce copper products, including brass products such as battery terminals.

-

2024-09-11Operators can specify when to use which tool through programming instructions, which allows multiple processes to be completed in a single setup cycle, increasing productivity and part consistency.

-

Participating in the Industrial Trade Association of Singapore (ITAP) on October 14-16, 2024, we as exhibitors need to pay attention to these.

-

This successful acceptance not only consolidates the cooperation relationship between us and our Russian customer, but also lays a solid foundation for more extensive cooperation in the future.

-

Gear CNC chamfering machine, as a precision machining equipment, plays an increasingly important role in many industries.

-

Compared with traditional gear machining methods, the CNC gear rolling machine has higher machining accuracy and faster machining speed, and also greatly reduces the requirements for operator skills.

-

2024-08-07A tool grinder is a precision machining equipment mainly used to repair or manufacture metal cutting tools such as drills, milling cutters and turning tools.

-

2024-07-26As an efficient gear processing equipment, four-axis gear shaper plays an important role in modern machinery manufacturing industry.