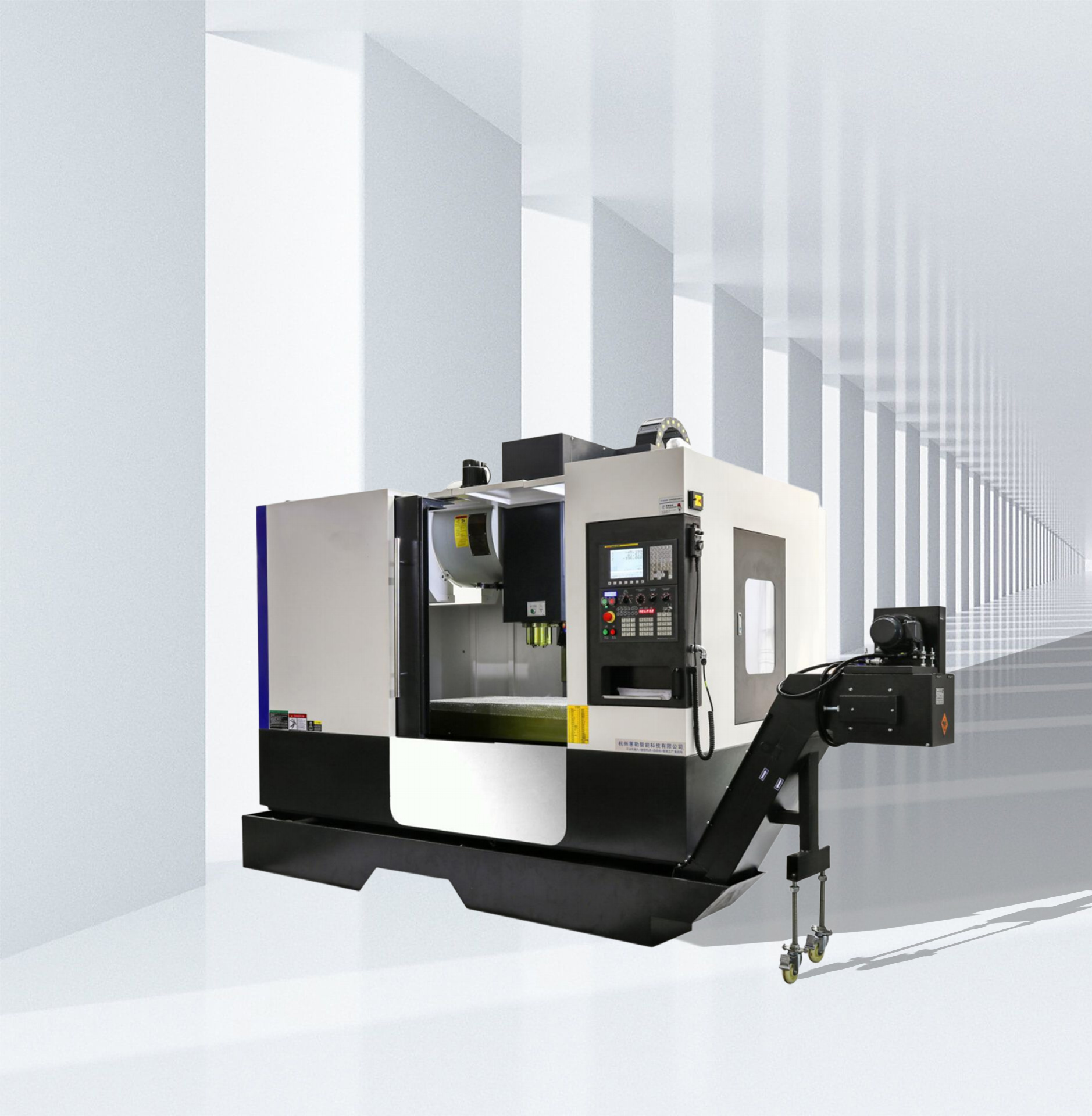

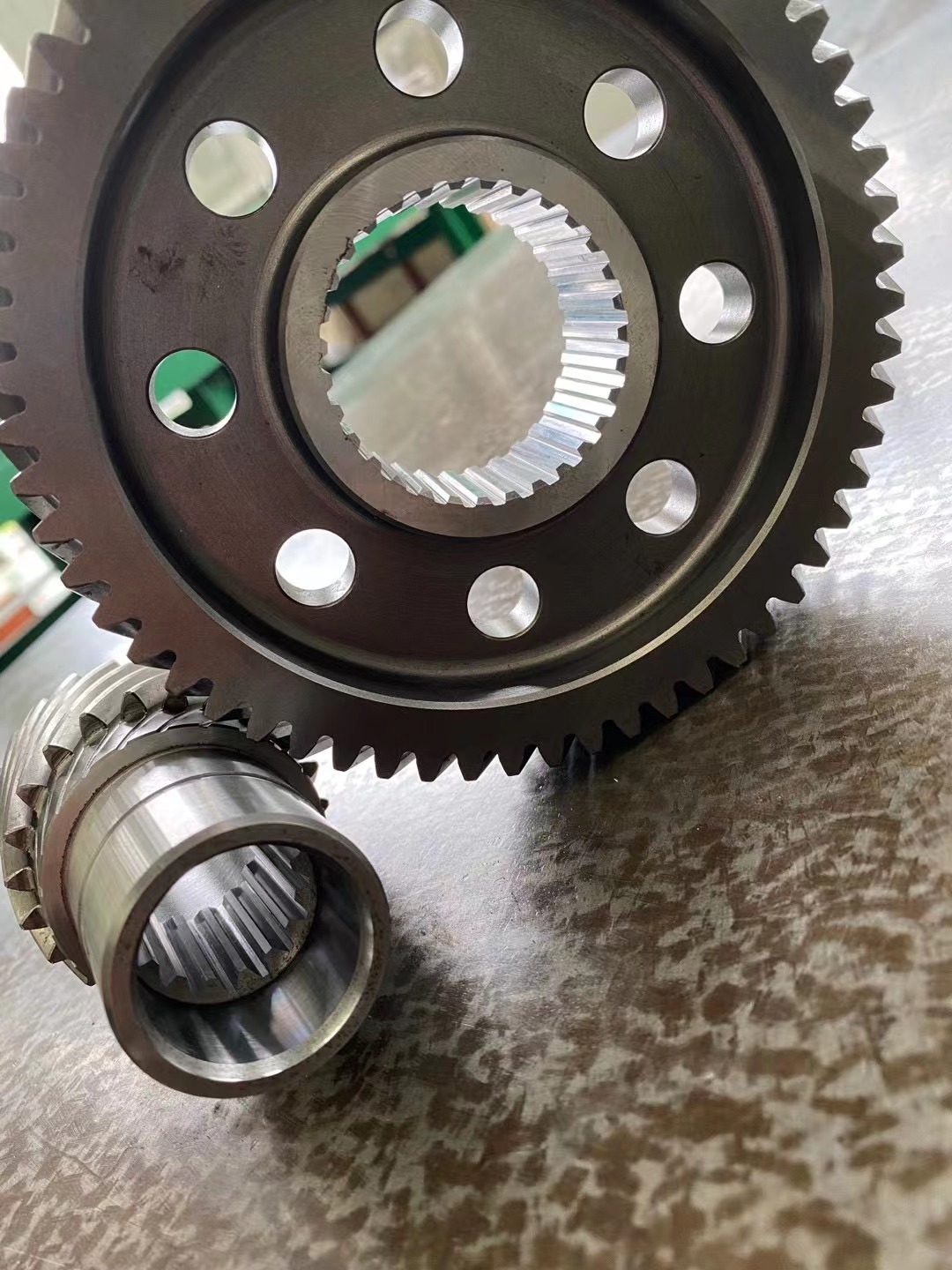

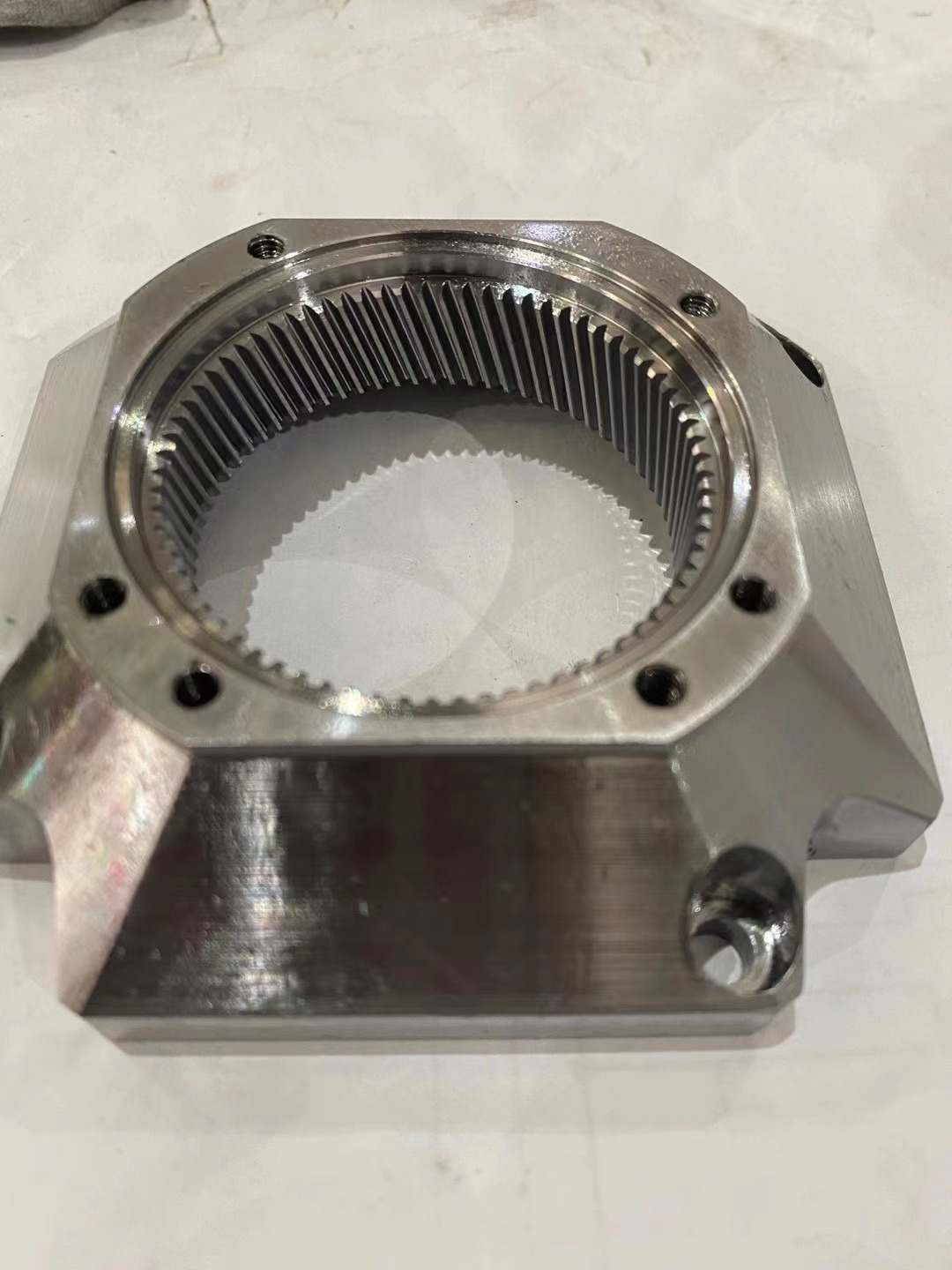

Vertical CNC Broaching Machine for Internal Round/Spline/Involute Tooth Gear

Vertical CNC Broaching Machine for Internal Round/Spline/Involute Tooth Gear

● Provide Broaching cutters

● Provide Broaching grinder

Δ The GK57 series of upward-pulling vertical CNC internal broaching machines can be used to broach the surface of internal bores of various geometries with high productivity and are suitable for mass production (e.g. round bores, spline bores, involute toothed internal spline bores, etc.);

Δ The machine uses a broaching method in which the broach does not move, and the workpiece moves upwards, which greatly improves the broaching accuracy of the workpiece.We can customize fully-automated drawing centers for loading and unloading according to customer requirements,consisting of loading, conveyor, unloading and drawing machines, which can also be connected to other machines for in-line inspection, without the need for a floor pit due to the low operating surface. The machine tool has automatic brushmechanism(also available on request with automatic rotating brush mechanism),which can extend the use life of cutting tools;

Δ The machine is hydraulically driven and works smoothly. The machine is capable of step-less speed regulation, is equipped with an overload safety device and has automatic cycle, sectional cycle and individual spot adiustment functions, The machine is protected by electrical and mechanical devices. All operations are done at the main button, which is easy to operate,safe and reliable.

Model | L5705 | GK5710 | LJ5720 | LK3130 Horizontal | LGK55740 | Unit |

Rated tension | 50 | 100 | 200 | 300 | 400 | KN |

Rated stroke | 800 | 1250 | 1600 | 2500 | 2000 | mm |

Broaching speed | 1~10 | 1~10 | 1~7 | 0.5-80 | 1-6 | m/min |

Range of broach length | 500~900 | 600~1400 | 700~1700 | / | / | mm |

Return speed | 2~20 | 2~20 | 1~15 | 7-12 | 1-20 | m/min |

Workbench size(LxW) | 350×300 | 410×340 | 600×420 | / | 625×565 | m/min |

Height of loading and unloading | ≤910 | ≤935 | ≤1100 | / | ≤1575 | m/min |

Main motor power | 7 | 17 | 36 | / | 54.71 | kW |

Total motor power | 14 | 24 | 41 | / | 62 | kW |

Broach moves upward speed | 1~5 | 1~5 | 1~20 | 1~15 | 1~5 | m/min |

Broach move down speed | 1~5 | 1~5 | 1~20 | 1~15 | 1~5 | m/min |

Max.hole diameter for faceplate | Φ75 | Φ60 | Φ100 | Φ300-Φ1000 | Φ150 | mm |

Maximum workpiece outside diameter*thickness | φ190×80 | Φ200×90 | Φ340×180 | 160 | Φ300×200 | mm |

Net weight of machine tool | 4700 | 8800 | 12000 | 35000 | 25500 | kg |

Workspace of the machine tool(LxWxH) | 2800×2700×4000 | 3600×3000×4800 | 2900×4050×5100 | 8400x4500x3200 | 3050 ×5950 ×5600 | mm |

1.What are your normal lead times?

Normally, 30 to 60 days

2.What kind of package do you offer?

Standard wooden case packing

3.Do you have certification of your machine?

CE certificate

4.How about the warranty service?

24 months

5.How about the installation and commissioning?

we will enclose the production specification with the machine, and we could provide the video online to you, and our engineers are available to debug machinery overseas.

6.How to select the suitable machine?

Pls tell us the machine you need, Includes drawings,specifications and other requirements.

7.How to do it if we meet the issue during the operation?

We provide completely after sales service, and our engineers are available to service machinery overseas.

8.If we want to learn how to operate the machine, Can you provide it?

Yes, we have special service team which will offer you professional guidance.