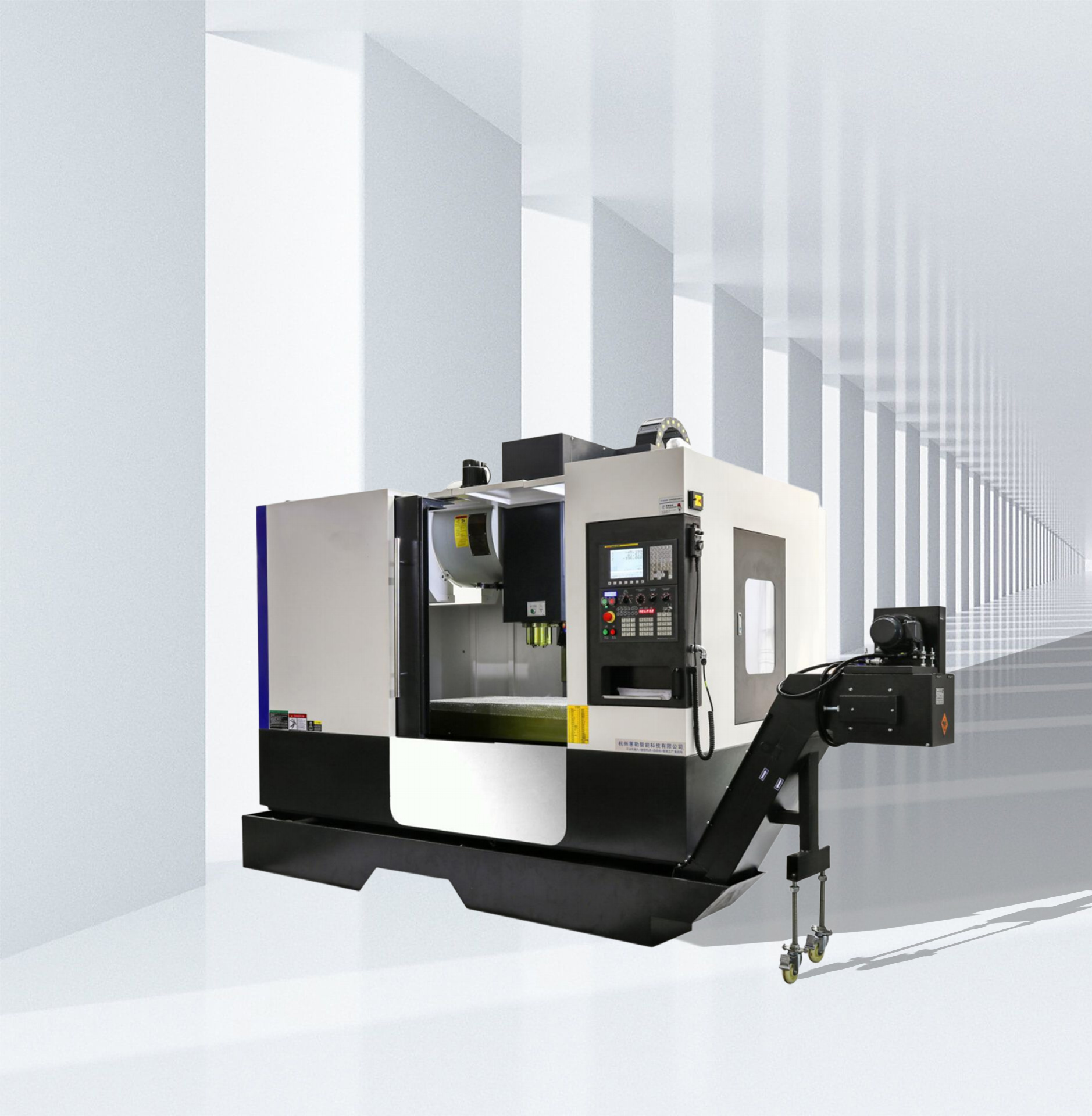

OEM CNC-Machine-Tools 5 Spindle Axis Milling Lathe Machine for Tooth Shape of Gear

OEM CNC-Machine-Tools 5 Spindle Axis Milling Lathe Machine for Tooth Shape of Gear

● Spindle Max Speed: 8000 rpm;

● We can provide professional technical solutions;

EM800A | S.A.E. | METRIC |

Travel | ||

X Axis | 32" | 800 mm |

Y Axis | 20" | 500 mm |

Z Axis | 20" | 500 mm |

Spindle Nose to Table | 6"-26" | 150-650 mm |

Spindle Center to Column Guideway | 22" | 550 mm |

Table | ||

Length | 40" | 1000 mm |

Width | 20" | 500 mm |

T-Slot Width | 0.7" | 18 mm |

T-Slot Center Distance | 4" | 90 mm |

Number of Std T-Slots | 5 | 5 |

Table Loading capacity | 882 LB | 400 Kg |

Table to the Ground | 36" | 900 mm |

Spindle | ||

Max Rating | (10/15) hp | (7.5/11) Kw |

Max Speed | 8000 rpm | 8000 rpm |

Max Torque | 54 ft-lb | 72 Nm |

Drive Mode | Synchronous Belt Drive | |

Taper/Specification | ISO 7/24Taper NO.40 | |

Feed Rate | ||

Rapids on X/Y/Z | 1890/1890/1890 IPM | 48/48/48 m/min |

Max Cutting | 393.7 IPM | 1-10000 mm/min |

Min Feed Rate | 0.0000394'' | 0.001 mm |

Axis Motors | ||

Drive Mode for X\Y\Z | Direct Inline Drive | |

Servo Motor Speed for X\Y\Z | 3000 rpm | |

Diameter of Ball Screw for X\Y\Z | ø1.6" | ø40 mm |

Ball Screw Pitch for X\Y\Z | 0.6" | 16 mm |

ATC | ||

Tool Magazine | Vertical Disc Type with Manipulator | |

Capacity | 24-Tools | |

Tool Shank | BT-40 | |

Shank Bolt | P-40T( 45°) | |

Max Tool Diameter(full) | ø3.1" | ø80 mm |

Max Tool Diameter (no adjacent tools) | ø5.9" | ø150 mm |

Max Tool length | 11.8" | 300 mm |

Max Tool Weight | 18 LBS | 8 Kg |

Tool-to-Tool Changing Time | 2.5 secs | 2.5 secs |

Dimension & Power Capacity | ||

Machine Weight | 11023 LBS | 5000 Kg |

Machine Height | 101" | 2550 mm |

Machine Area (Length*Width) | 99"*93" | 2500 mm*2350 mm |

CP | 20 KVA | |

Precision | ||

Positioning Accuracy | 0.000197" | 0.005 mm |

Repeated Positioning Accuracy | 0.000118" | 0.003 mm |

thers | ||

Air Required | 87~116 psi | 6~8 Bar |

Coolant Capacity | 40 us gal | 180 L |

Lubricating Oil Capacity | 0.79 us gal | 3 L |

Control | FANUC Series 0i - MODEL F | |

Δ How to choose equipments?

This guide will help you to choose the best press machine equipments for your project.

1.STANDARD CONFIGURATION

CONTENT | QUANTITY | NOTE |

FANUC Control | 1 | |

10.4 Inch TFT Color Display | 1 | |

Heat Exchanger for Electric Control Cabinet | 1 | |

Automatic Lubrication Device | 1 | |

Full Frame Protection | 1 | |

Electric Control Cabinet Dustproof Device | 1 | |

Signal Lamp | 1 | |

Rigid Tapping | 1 | |

Cutting Fluid Cooling Device | 1 | |

Spindle Air Curtain Protection | 1 | |

LED Working Lamp | 1 | |

Feet Bolt and Heel Block | 6 | |

Air Blowing Device | 1 | |

Work-box/Kit | 1 | |

Transformer | 1 | |

Triaxial Protective | 1 | |

Safety Switch Device of Door | 1 | |

RS232Communication Interface & CF Card Slot | 1 | |

Cleaning Air Gun Interface | 1 | |

Pneumatic unclamping Button | 1 | |

Detachable Hand Wheel | 1 | |

Oil-Water Separating Device | 1 | |

Open M codes Function | 4 | |

PLC & 4th and 5th axis Function is filled and opened | 1 | |

Water Cooling Side Through | 1 | |

Vertical Disc type Magazine with Manipulator | 24 | CAM Technology |

2.STANDARD OPTIONAL CONFIGURATION

CONTENT | QUANTITY | NOTE |

Roller Linear Guide Rail for 3 Axis | 1 | |

Water Cooling Center Through | 1 | 20 Bar |

Automatic Power Off | 1 | |

Chain Chip Conveyor | 1 | Standard or Rear Type |

Air Conditioner for Electric Cabinet | 1 | |

Water Gun | 1 | |

32-tools Magazine | 1 | |

10000 rpm & 12000 rpm Spindle | 1 | With Oil Cooling |

RENISHAW TRS2 | 1 | |

Automatic Door | 1 |

1.What are your normal lead times?

Normally, 30 to 60 days

2.What kind of package do you offer?

Standard wooden case packing

3.Do you have certification of your machine?

CE certificate

4.How about the warranty service?

24 months

5.How about the installation and commissioning?

we will enclose the production specification with the machine, and we could provide the video online to you, and our engineers are available to debug machinery overseas.

6.How to select the suitable machine?

Pls tell us the machine you need, Includes drawings,specifications and other requirements.

7.How to do it if we meet the issue during the operation?

We provide completely after sales service, and our engineers are available to service machinery overseas.

8.If we want to learn how to operate the machine, Can you provide it?

Yes, we have special service team which will offer you professional guidance.