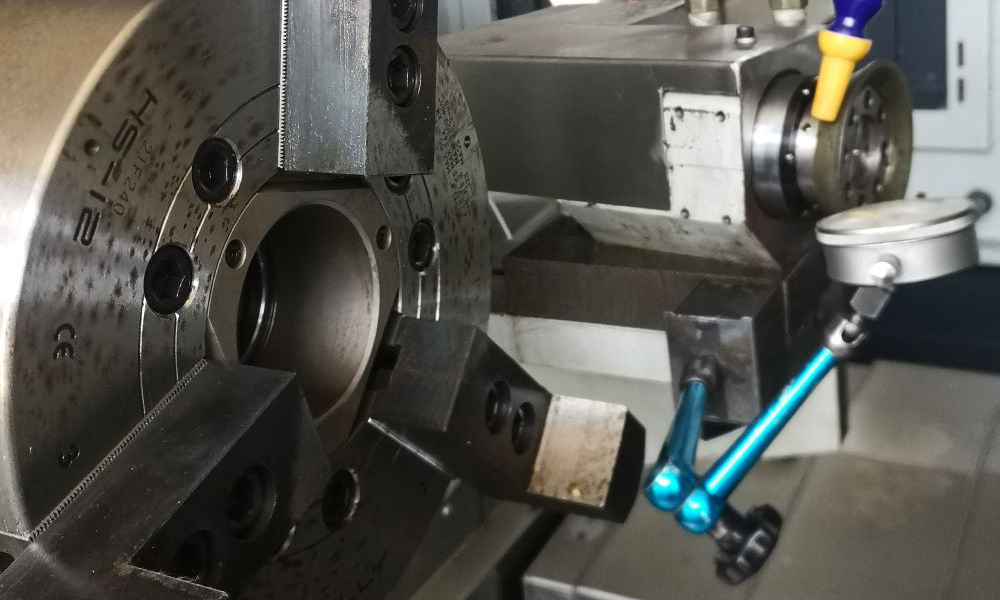

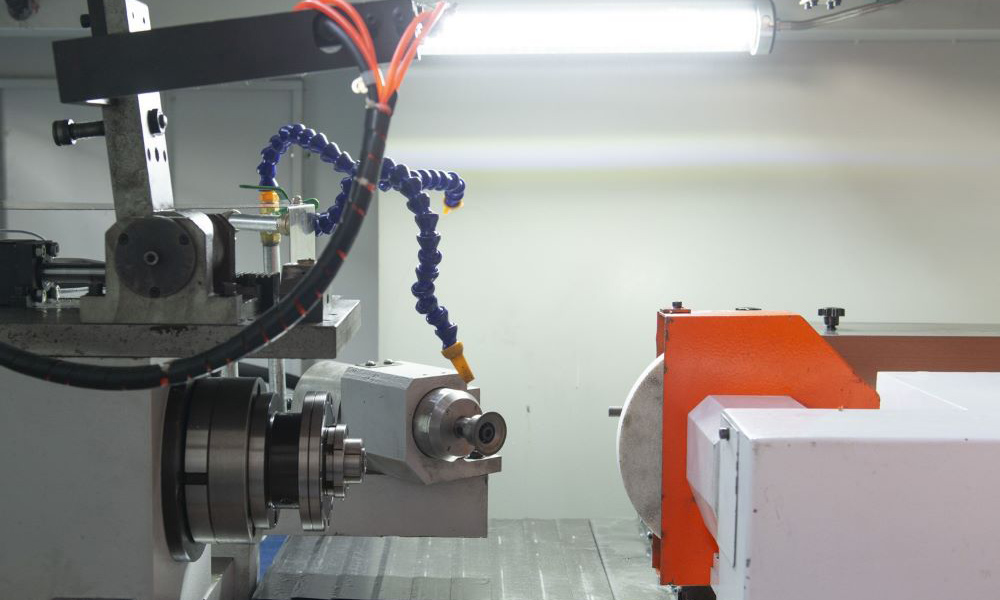

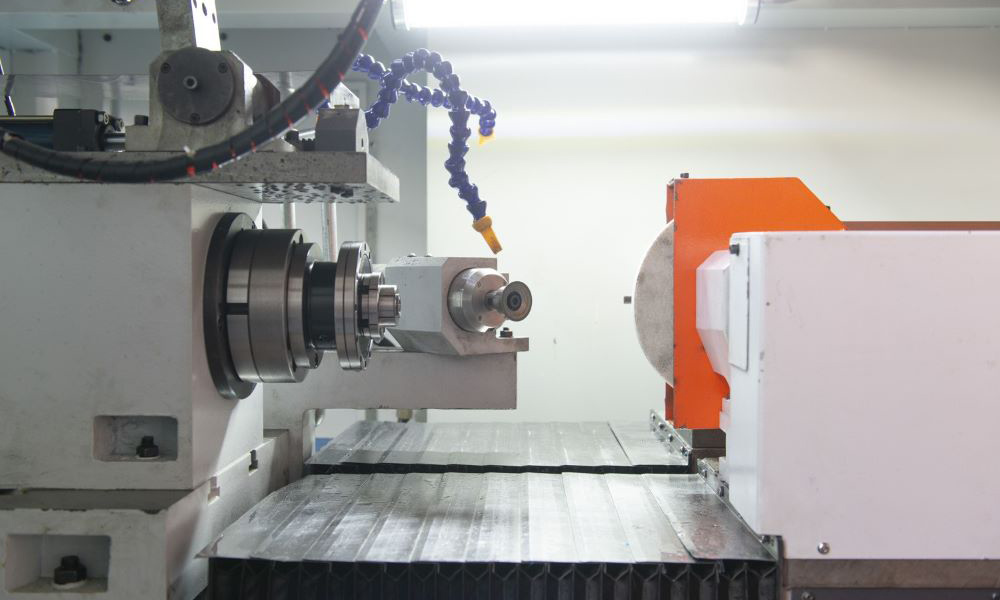

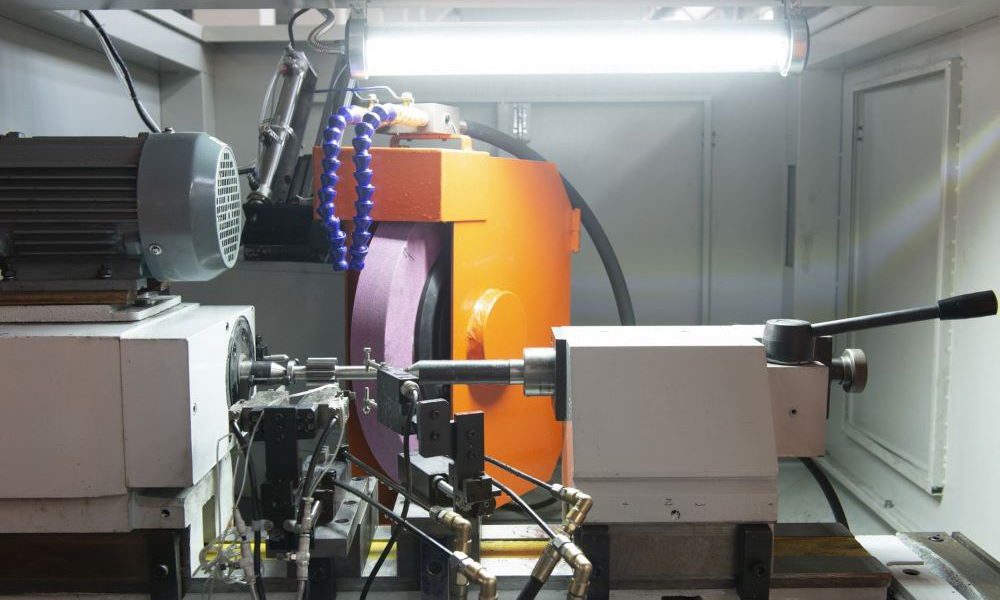

High Precision Horizontal CNC Internal Grinding Machine with Max.ID 500mm

High Precision Horizontal CNC Internal Grinding Machine with Max.ID 500mm

● Grinding Diameter Range:6-320mm

● Grinding Accuracy:Ra 0.32µm

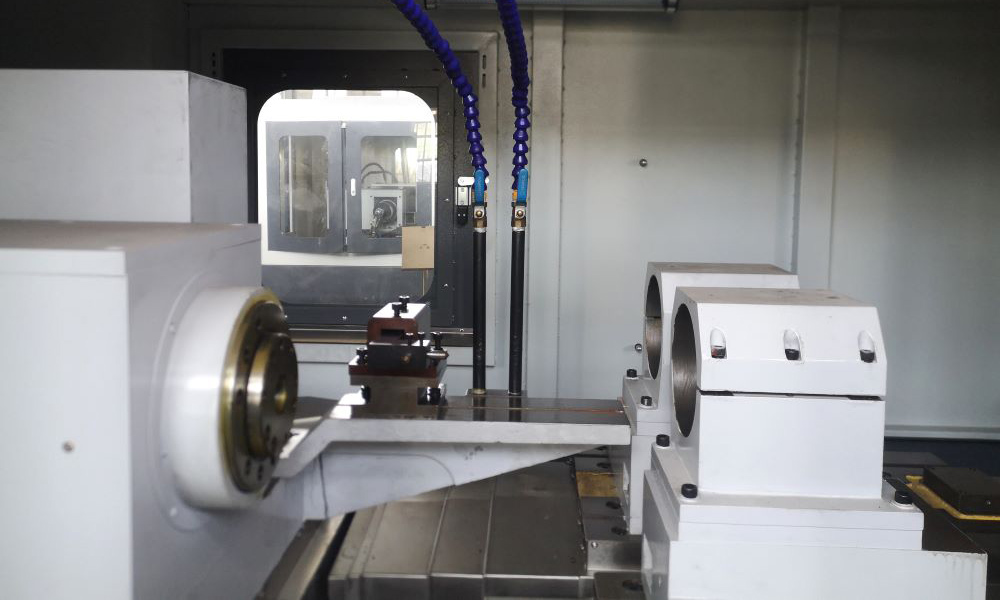

Δ This machine is a two axis (X-axis, Z-axis) CNC Internal Grinder, which is mainly used to grind the inner hole, step hole, iner end face and outer end face of the work piece. The grinding cycle is completed automatically

Δ (with automatic feed,withdrawal , rough grinding and finegrinding); Automatic dressing of grinding wheel,automatic compensation, etc.

Δ The machine tool is fixed by the work piece box, the worktable moves left and right.and the grinding wheel frame do the back and forth fedingmovement. The movement of the worktable and grinding wheel frame is driven by the servo motor through the ball crew, both of which adoptlinear guide rails.

Δ The rotation speed of work piece spindle and grinding wheel spindle are controlled by frequency converer to reaize stepless speed regulaton.

Δ The machine tool adopts a front movable operation box and an independent electrical cabinet. The protective cover shell has two differentstyles of semi closed or fully closed for users optional.

Model of machine tools | Horizontal GK250 | |

The range of grinding diameter of hole(mm) | 100-500 | |

Maximum grinding depth (mm) | 500 | |

Swing diameter of work piece (mm) | Inside the shell(mm) | 510 |

Outside the shell (mm) | 720 | |

The maximum stroke of feeding slide(mm) | 200 | |

The maximum stroke of workbench(mm) | 730 | |

Maximum rotation angle of lather head(° ) | 30° | |

Rotating speed of work piece (r/min) | 30-500stepless speed regulation | |

Rotating speed of grinding wheel (r/min) | 2000-10000(stepless speed regulation) | |

Motor power of workpiece(kw) | 4 | |

Motor power of grinding wheel(kw) | 5.5 | |

Motor power of X-axis servo motor(kw) | 2 | |

Motor power of Z-axis servo motor(kw) | 4 | |

The power of oil pressure motor (kw) | 0.55 | |

Cooling motor power (kw) | 0.09×2 | |

Rated power(kw) | 17.8 | |

Maximum speed of workbench m/min | 6 | |

Grinding speed m/min | 0-4 | |

Feed speed of grinding wheel m/min | 5 | |

X-axis minimum resolution mm | 0.001 | |

Z-axis minimum resolution (mm) | 0.001 | |

Maximum load capacity of workpiece (kg) | 300 | |

Flow of cooling pump(L/min) | 30 | |

The pressure of hydraulic system (MPa) | 0.4 | |

Flow of oil pump(L/min) | 25 | |

The weight of machine tools(kg) | 5600 | |

Machine overall dimension(mm) | 4000× 1900×2000 | |

Roundness of internal hole(um) | 3 | |

Machining precision | Cylindricity of internal hole(um) | 5 |

Surface roughness of internal hole (um) | Ra0.63 | |

Roughness of end face(um) | Ra0.8 | |

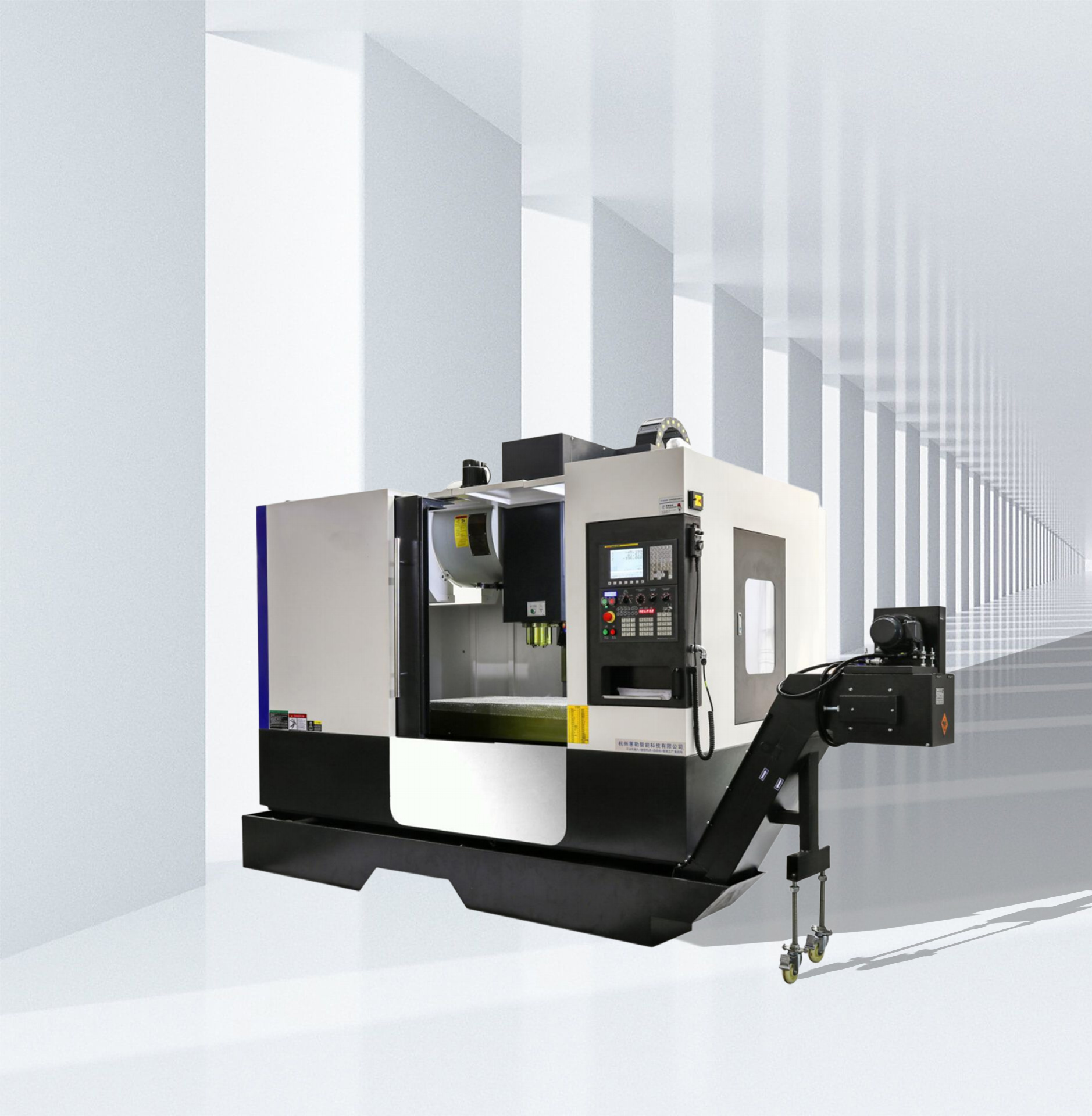

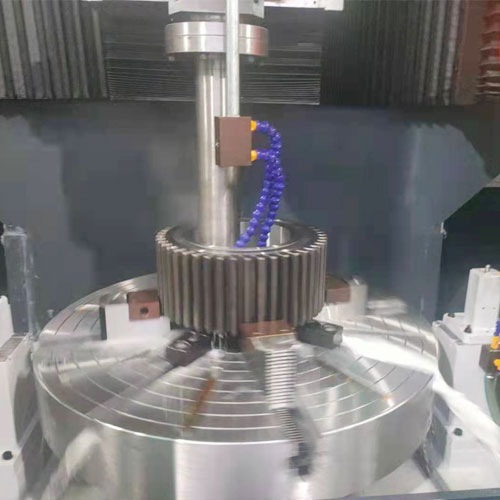

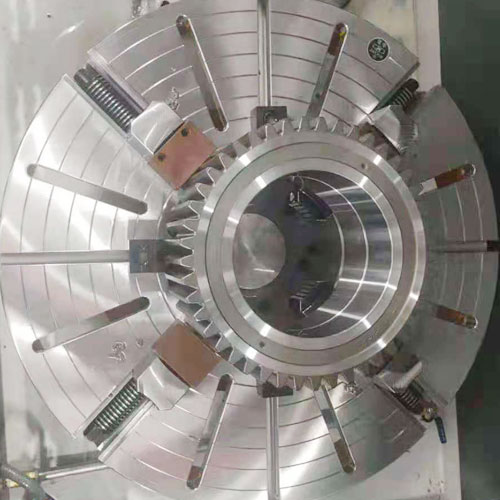

Vertical CNC internal and external compound grinding machine

Machine model | GKLF28-300 | GKLF28-500 | GKLF28-1000 | GKLF28-1500 | GKLF28-2000 | GKLF28-2500 | GKLF28-3000 |

Max. Grinding inner diameter (mm) | 300 | 500 | 1000 | 1500 | 2000 | 2500 | 3000 |

Max. Grinding outer diameter (mm) | 400 | 600 | 1200 | 1800 | 2200 | 2700 | 3200 |

Max. Grinding depth (mm) | 400 | 500 | 600 | 700 | 750 | 800 | 850 |

MaxDiameter of electromagnetic chuck (mm) | 400 | 500 | 1000 | 1800 | 2000 | 2700 | 3200 |

Maximum work piece bearing capacity (KG) | 500 | 1000 | 3000 | 5000 | 8000 | 10000 | 12000 |

Maximum work piece rotation diameter (mm) | 500 | 800 | 1300 | 2000 | 2300 | 3000 | 3500 |

Max. Stroke of X 1 axis (mm) | 500 | 800 | 1000 | 1200 | 1300 | 1500 | 1800 |

Max. Stroke of X 2 axis (mm) | 500 | 800 | 1000 | 1200 | 1300 | 1500 | 1800 |

Max. Stroke of Z1 axis (mm) | 500 | 600 | 700 | 800 | 850 | 900 | 1000 |

Max. Stroke of Z2 axis (mm) | 500 | 600 | 700 | 800 | 850 | 900 | 1000 |

X1 X2 axis resolution (mm) | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 |

Z1 Z2 axis resolution (mm) | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 |

X1 axis moving speed (m/min) | 6 | 6 | 6 | 10 | 10 | 10 | 10 |

X2 axis moving speed (m/min) | 6 | 6 | 6 | 10 | 10 | 10 | 10 |

Z1 axis moving speed (m/min) | 6 | 6 | 6 | 10 | 10 | 10 | 10 |

Z2 axis moving speed (m/min) | 6 | 6 | 6 | 10 | 10 | 10 | 10 |

Work table rotation speed (rm) | 10-120 | 10-80 | 10-60 | 10-60 | 10-60 | 10-50 | 10-50 |

Overall dimensions of machine tool (mm) | 2600x2400x2800 | 3200x3200x3800 | 3800x3500x3800 | 4500x3800x4300 | 5500x4200x4600 | 5800x4800x4800 | 6800x5200x5000 |

Weight of machine tool (KG) | 8500 | 13500 | 23000 | 55000 | 65000 | 83000 | 98000 |

1.What are your normal lead times?

Normally, 30 to 60 days

2.What kind of package do you offer?

Standard wooden case packing

3.Do you have certification of your machine?

CE certificate

4.How about the warranty service?

24 months

5.How about the installation and commissioning?

we will enclose the production specification with the machine, and we could provide the video online to you, and our engineers are available to debug machinery overseas.

6.How to select the suitable machine?

Pls tell us the machine you need, Includes drawings,specifications and other requirements.

7.How to do it if we meet the issue during the operation?

We provide completely after sales service, and our engineers are available to service machinery overseas.

8.If we want to learn how to operate the machine, Can you provide it?

Yes, we have special service team which will offer you professional guidance.